Managing parts in the truck and bus industry is a critical aspect of maintaining operational efficiency and ensuring customer satisfaction. The dynamic and fast-paced nature of this industry demands a robust management system that can handle the complexities of inventory control, supply chain coordination, quality assurance, and beyond.

Effective management not only minimizes vehicle downtime but also enhances overall service quality, making it a vital component of any successful truck and bus business.

Managing parts in the truck and bus industry, however, is a multifaceted and intricate task that presents numerous challenges. These challenges, although diverse, are not unique and are commonly encountered by many truck and bus businesses.

From inefficient handling to streamlined workflows, understanding these obstacles and how to overcome them is crucial for maintaining operational efficiency and customer satisfaction.

In this blog, we’ll highlight the importance of efficient parts management and discuss the benefits it brings to truck and bus businesses. We’ll also explore common challenges and how an end-to-end cloud-based management solution can help overcome these obstacles and improve operations.

7 reasons why parts management is crucial for trucks & buses businesses

Effective management not only minimizes vehicle downtime but also enhances overall service quality, making it a vital component of any successful truck and bus business.

- Minimizing vehicle downtime: Efficient management ensures that necessary stock is always available, reducing the time vehicles spend out of service. This leads to higher operational efficiency and better service delivery.

- Enhancing customer satisfaction: Maintenance and repairs can be conducted promptly when parts are readily available, ensuring that customers experience minimal delays. Satisfied customers are more likely to return and recommend the business to others.

- Optimizing inventory levels: Proper management helps maintain the right balance of inventory, preventing both overstocking and understocking. This optimization reduces holding costs and ensures that capital is not unnecessarily tied up in excess inventory.

- Improving supply chain efficiency: A streamlined management system facilitates better coordination with suppliers, ensuring timely delivery and reducing bottlenecks. This enhances the overall efficiency of the supply chain.

- Ensuring quality and safety: Rigorous management includes stringent quality checks and standards, ensuring that only high-quality products are used. This is crucial for maintaining vehicle safety and performance.

- Facilitating parts tracking and accountability: Effective management systems track parts throughout their lifecycle, from procurement to installation. This tracking aids in maintenance planning, warranty management, and accountability.

- Reducing operational costs: By preventing unnecessary purchases and optimizing usage, businesses can significantly reduce their operational costs. Efficient management also helps avoid emergency purchases, which are often more expensive.

Key parts management challenges

Understanding these challenges is crucial for implementing effective strategies and solutions to streamline parts management processes and improve overall operational efficiency.

By identifying and addressing these common obstacles, truck and bus businesses can ensure they are well-equipped to maintain optimal performance and meet customer expectations.

- Inventory management: One of the primary challenges is keeping track of inventory. Overstocking can lead to high holding costs, while understocking can result in delays and unmet customer needs. It’s essential to strike the right balance to ensure optimal inventory levels.

- Supply chain complexities: The truck and bus industry often involves coordinating with multiple suppliers to ensure timely delivery. Managing these complex supply chains can be challenging, leading to bottlenecks and inefficiencies.

- Quality assurance: Maintaining stringent quality standards for all parts is crucial for safety and performance. However, consistently achieving these standards can be difficult, especially when dealing with a large number of suppliers and products.

- Parts tracking: Tracking the lifecycle, from procurement to installation, is essential for maintenance and warranty purposes. However, this process is often managed inefficiently, leading to delays and errors.

- Parts replacements: Identifying and replacing faulty or worn-out parts quickly and accurately is crucial for minimizing vehicle downtime and maintaining service quality. However, this process can be challenging, especially when dealing with a large number of different products.

- Obsolete parts management: Managing obsolete parts involves balancing the disposal or recycling of outdated components with the introduction of new ones. This process can be complex and time-consuming, especially when dealing with a large inventory.

- Emergency response: Responding to urgent needs requires a well-coordinated system that minimizes downtime and ensures quick turnaround. However, without the right tools and processes in place, this can be challenging to achieve.

The need for a comprehensive parts solution

While some businesses have implemented temporary fixes to address these challenges, the real solution lies in a comprehensive system that integrates various departments and ensures seamless communication across the entire value chain.

This is where A365 comes into play.

How A365 solves parts management challenges

A365 is a comprehensive solution built on the backbone of Microsoft technologies like Microsoft Dynamics 365, Power Platform, Copilot, and the Common Data Model, designed to simplify every aspect of parts management activities in the truck and bus industry.

By leveraging the power of A365, businesses can deliver exceptional customer experiences, enhance supplier relationships, streamline processes, and reduce costs.

Here’s how A365 adds value to truck and bus businesses:

A365 enables businesses to efficiently manage ordering and inventory, preventing overstocking and understocking. By leveraging real-time data and analytics, businesses can make informed decisions about inventory levels, ensuring they always have the right items on hand.

2.Customized parts and inventory optimization

A365 provides businesses with access to standardized and extended features, ensuring that inventory levels are optimized to meet demand without excess. With A365’s advanced forecasting and planning tools, businesses can ensure that they always have the right products on hand, minimizing downtime and improving customer satisfaction.

3.Streamlined communication for parts availability

A365 ensures that information about stock availability is communicated effectively across departments, reducing delays and improving service quality. By providing real-time visibility into inventory levels and order statuses, A365 enables businesses to quickly respond to customer needs.

4.Integrated vehicle maintenance and servicing

A365 enables businesses to develop a functional connection between parts management and vehicle maintenance, ensuring availability. By integrating the two, businesses can reduce vehicle downtime, improve service quality, and enhance customer satisfaction.

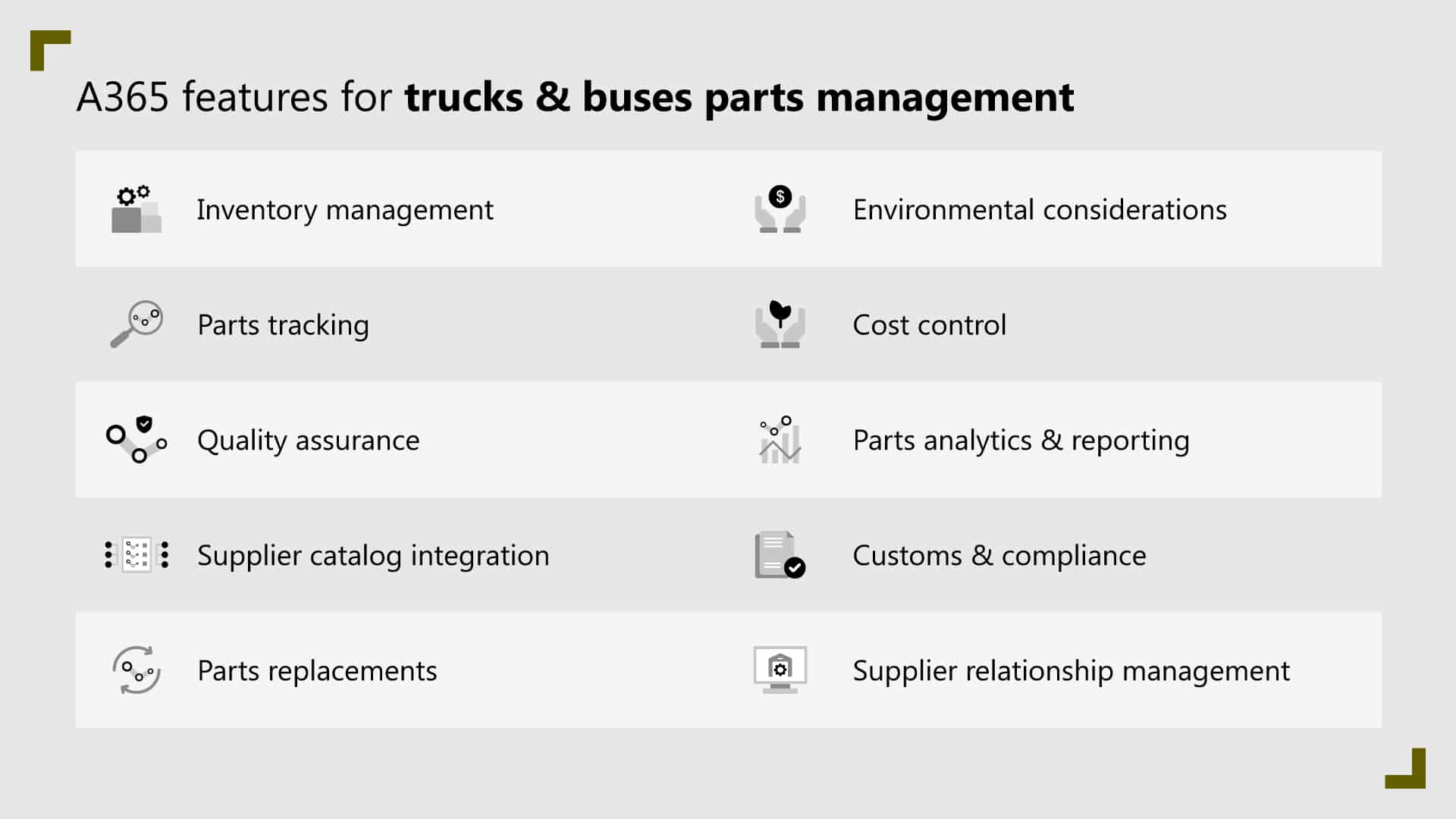

A365 features for trucks & buses parts management

A365 offers a range of features tailored to the specific needs of the truck and bus industry, including:

- Inventory management: Advanced tools for tracking and managing inventory, ensuring that businesses always have the right parts on hand.

- Parts tracking: Comprehensive tracking systems for monitoring throughout their lifecycle, from procurement to installation.

- Quality assurance: Tools for ensuring all products meet high-quality standards through rigorous checks and inspections.

- Supplier catalog integration: Seamless integration with supplier catalogs for efficient ordering and inventory management.

- Parts replacements: Streamlined processes for identifying and replacing faulty or worn-out parts quickly and accurately.

- Environmental considerations: Tools for managing inventory in an environmentally responsible way, including recycling and disposal options.

- Cost control: Tools for monitoring and controlling expenses, ensuring that businesses stay within budget.

- Parts data & reporting: Detailed reporting tools to help businesses make informed decisions.

- Customs & compliance: Tools for ensuring compliance with international trade regulations and standards, including customs and import/export requirements.

- Supplier relationship management: Tools for building and maintaining strong relationships with suppliers, ensuring that businesses have access to high-quality products and timely deliveries.

Unlock the potential of your truck and bus business with streamlined parts management using A365! Connect with our industry experts for a free consultation today and discover how A365 can revolutionize your operations. Don’t wait—reach out to us now!