From the towering cranes at construction sites to the powerful machines carving paths in the mining industry, the equipment sector powers the world’s most critical operations. Yet, behind every excavator, forklift, or forestry harvester is an equipment supply chain that can either drive success or bring operations to a grinding halt.

Whether you’re an importer, distributor, retailer, dealer, or service center, keeping the equipment supply chain running smoothly is a daily battle. Equipment downtime means lost revenue, frustrated customers, and costly delays. Stocking too much inventory ties up capital, while stocking too little risks losing sales. Compliance issues, unpredictable demand, and inefficient workflows add more layers of complexity. Simply put—getting the supply chain right isn’t just important; it’s mission-critical.

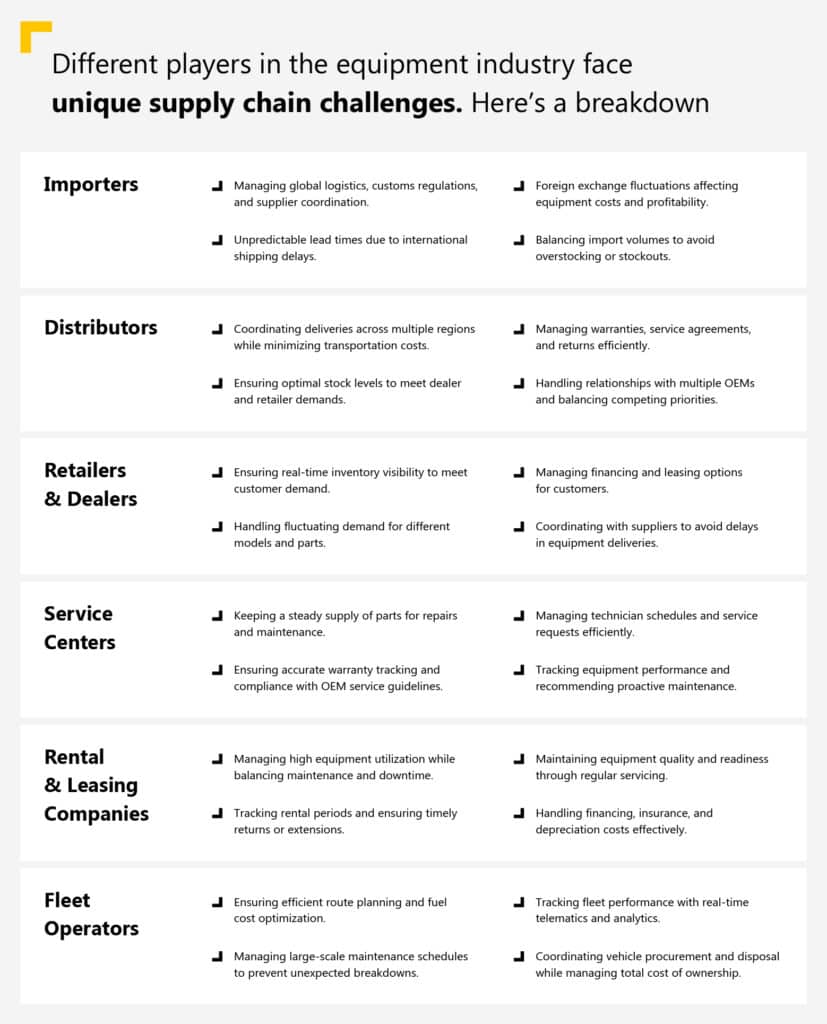

The equipment supply chain challenges by business type

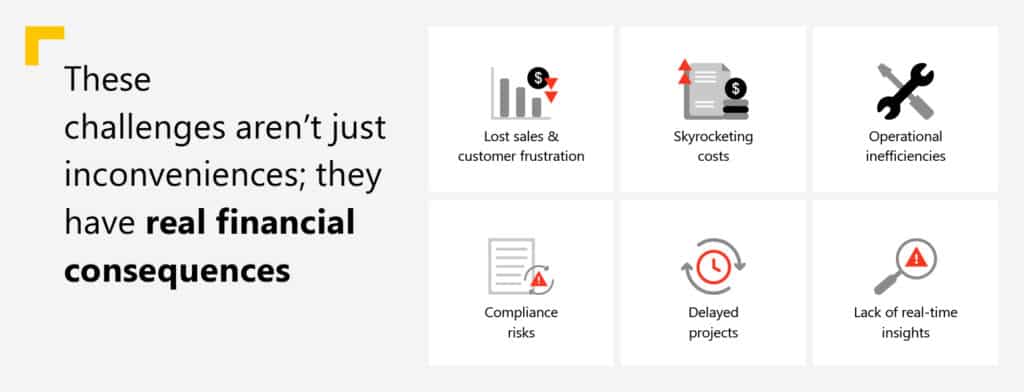

The hidden costs of a weak equipment supply chain

Have you ever had a machine sit idle because a critical part wasn’t available? Have you struggled to balance inventory levels across multiple locations?

If these sound familiar, you’re not alone. But the good news? There’s a better way.

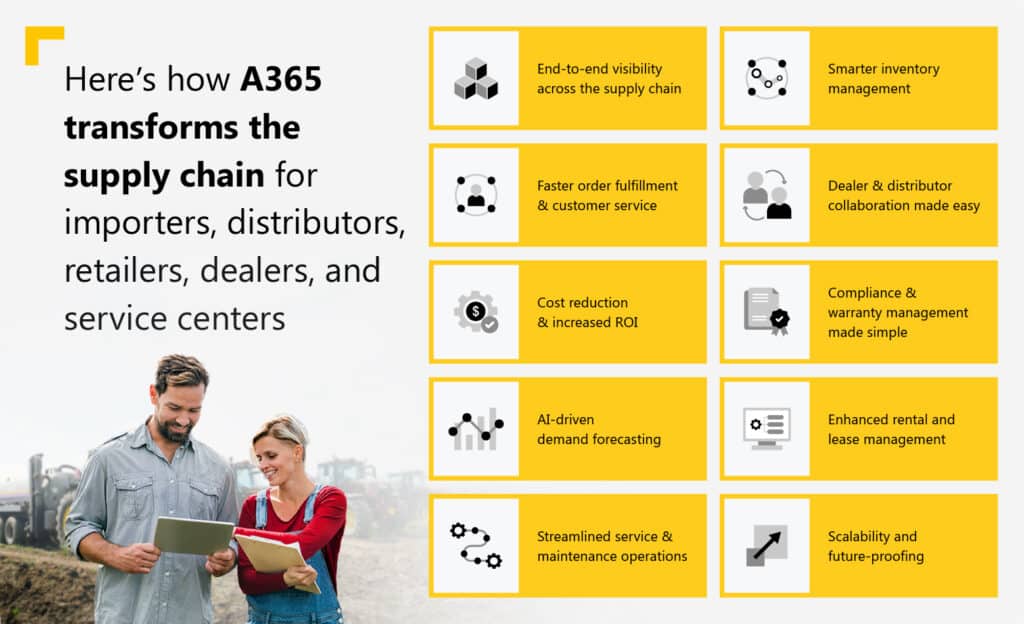

How A365 solves your equipment supply chain challenges

A365, built on Microsoft Dynamics 365, Azure, Copilot, Power Platform, and Dataverse, is an end-to-end, cloud-based solution designed to streamline supply chain operations for equipment businesses in forestry, construction, mining, and agriculture.

Whether you’re managing equipment sales, servicing, rentals, or distribution, A365 ensures seamless operations with powerful Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Dealer Management System (DMS), and Dealer Distribution Systems (DDS) capabilities.

- End-to-end visibility across the supply chain

No more blind spots. A365 connects every stage of your operations—inventory, sales, procurement, logistics, and service—into one unified platform. Real-time insights help you track equipment, monitor parts availability, and respond to demand fluctuations instantly.

- Smarter inventory management

Instead of guessing what to stock, let A365’s AI-driven analytics, powered by Microsoft Copilot, predict demand patterns. Keep just the right amount of inventory across all locations, reducing excess stock while ensuring critical parts and machines are always available.

- Faster order fulfillment & customer service

Delays in processing orders or servicing equipment can damage your reputation. A365 automates workflows to speed up order approvals, invoicing, and repair scheduling. Whether you’re managing dealer orders or service requests, A365 keeps everything moving efficiently.

- Dealer & distributor collaboration made easy

Communication gaps between suppliers, distributors, and retailers can lead to costly misunderstandings. A365’s DMS and DDS ensure seamless collaboration, making it easier to manage orders, returns, warranties, and service requests across multiple locations.

- Cost reduction & increased ROI

A365’s modular approach means you only invest in the tools you need while leaving the door open for future expansion. By streamlining workflows, reducing waste, and improving efficiency, businesses see immediate cost savings and long-term return on investment (ROI), especially with A365’s low Total Cost of Ownership (TCO).

- Compliance & warranty management made simple

Equipment businesses face strict regulatory and warranty requirements. A365 automates compliance tracking, ensuring equipment servicing, safety checks, and warranty claims are seamlessly managed—reducing risk and increasing customer trust.

- AI-driven demand forecasting

Unpredictable demand is one of the biggest challenges in supply chain management. A365 leverages AI-powered predictive analytics to forecast demand accurately, ensuring that the right equipment and parts are always available when needed.

- Enhanced rental and lease management

Many businesses in this sector rely on rental and leasing services. A365 helps track rental contracts, optimize fleet utilization, and manage maintenance schedules, ensuring maximum uptime and profitability.

- Streamlined service & maintenance operations

Service centers and dealers benefit from integrated maintenance tracking, allowing them to manage service requests, track parts usage, and schedule preventative maintenance, reducing downtime and increasing customer satisfaction.

- Scalability and future-proofing

The industry is evolving rapidly, and businesses need solutions that can scale with them. A365’s cloud-based platform ensures flexibility, scalability, and an evergreen solution that constantly evolves, allowing companies to expand operations without costly IT infrastructure investments.

Power new possibilities for your equipment business with A365

Equipment supply chains aren’t getting simpler. Global disruptions, shifting customer expectations, and increasing operational costs make it essential to rethink how we manage logistics, inventory, and service. A365 isn’t just a software solution; it’s a strategic advantage that helps businesses future-proof operations, stay ahead of competitors, and improve profitability.

Don’t let equipment supply chain inefficiencies hold you back—embrace the power of A365 and take your business to the next level.

Connect with us today to see how we can help your equipment business manage equipment supply chain issues, or explore our Digital Experience Center for a free, immersive look at how A365 can transform your operations.