In today’s automotive, trucks & buses, and equipment industries, one thing has become crystal clear: integration drives success. OEMs and dealers can no longer rely on disconnected systems or manual workarounds. They need seamless data flow, real-time visibility, and collaboration across the entire value chain.

This is exactly where Annata makes a difference. Powered by Microsoft Dynamics 365, Annata has developed a strong portfolio of OEM integrations designed to connect every stakeholder, from OEM platforms to dealer groups, into one unified ecosystem. The result? Smarter operations, stronger partnerships, and a better experience for customers at every touchpoint.

To dive deeper into this space, we sat down with Phil Hart, who recently joined Annata’s growing OEM Integrations team. With a career that spans automotive retail, SaaS providers, and now global solution delivery, Phil brings both industry and technical expertise to one of the most pressing areas in the business: creating integrations that are modular, adaptable, and future-ready.

Phil shared his thoughts on why OEM integrations matter, what challenges businesses face, and how Annata is helping reshape the future of connectivity in the automotive industry.

Let’s dive right in.

Q1. Phil, can you share a bit about your background and what brought you to Annata?

I joined Annata earlier this year to help manage the growing number of OEM requirements our partners need to operate their businesses. My journey started in the UK dealer network with brands like Volvo and Stellantis, where I worked across both sales and aftersales. That gave me first-hand experience of how important integrations are to keep a business running efficiently.

Over time, I transitioned into dealer management system providers, where I worked closely with customers and OEMs on their integration needs. I’ve been involved in roles ranging from support and product to consultancy and sales, which gave me a broad view of the industry.

What attracted me to Annata is the technology. A365 is built on Microsoft Dynamics 365 and Azure, designed to scale globally, adapt quickly, and deliver results through hundreds of knowledgeable partners. Combine that with Annata’s openness to evolve with customer requirements, and it felt like the right opportunity to make an impact.

Q2. From your experience, why are OEM integrations such a critical focus for automotive businesses today?

Q3. What are some of the biggest challenges companies face when trying to integrate with OEM platforms?

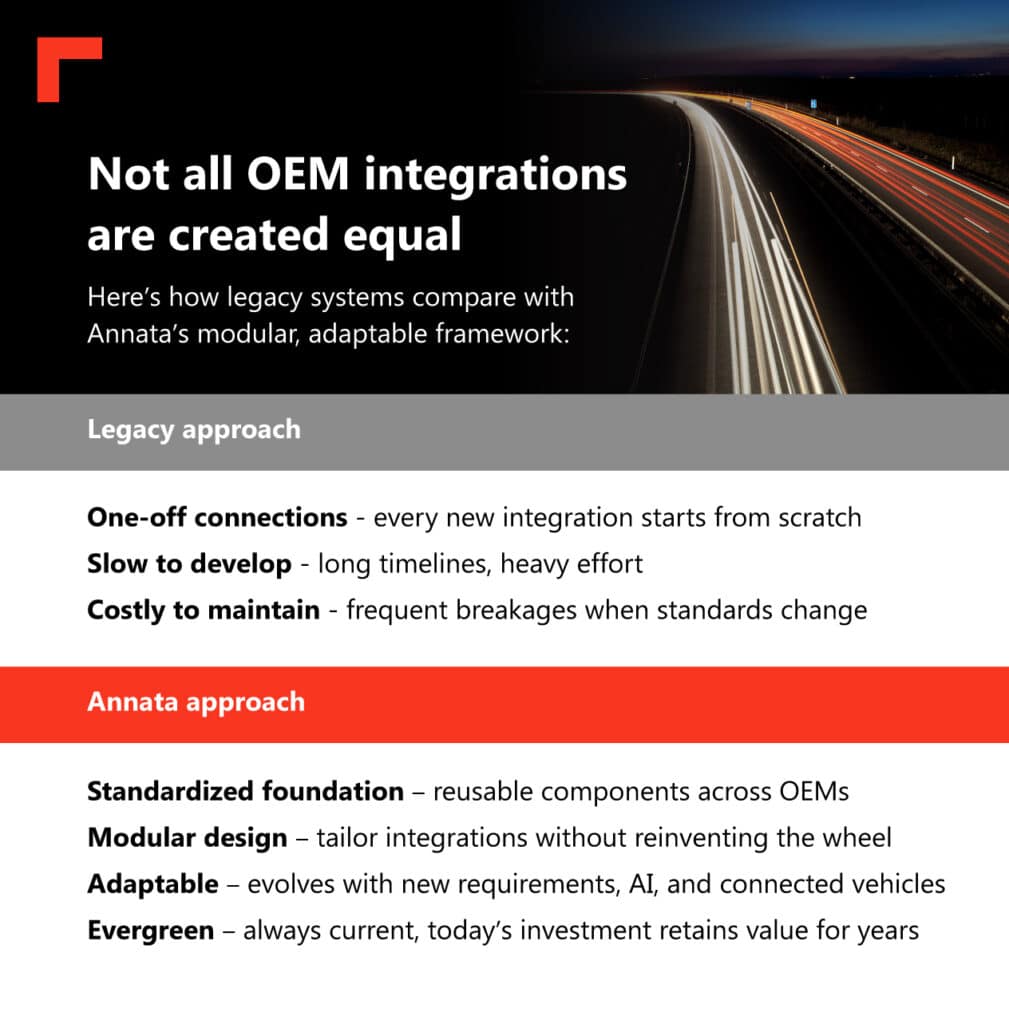

Integrations are often complex, expensive, and time-consuming. While each OEM may have different technical specifications, their goals are usually very similar. That is where Annata comes in.

With A365, we re-use standardized and modular OEM integration components. This means businesses don’t have to start from scratch for every new integration. It reduces effort, accelerates time to market, and ensures consistency across different systems and partners.

Q4. How does Annata’s approach simplify what is usually such a complex process?

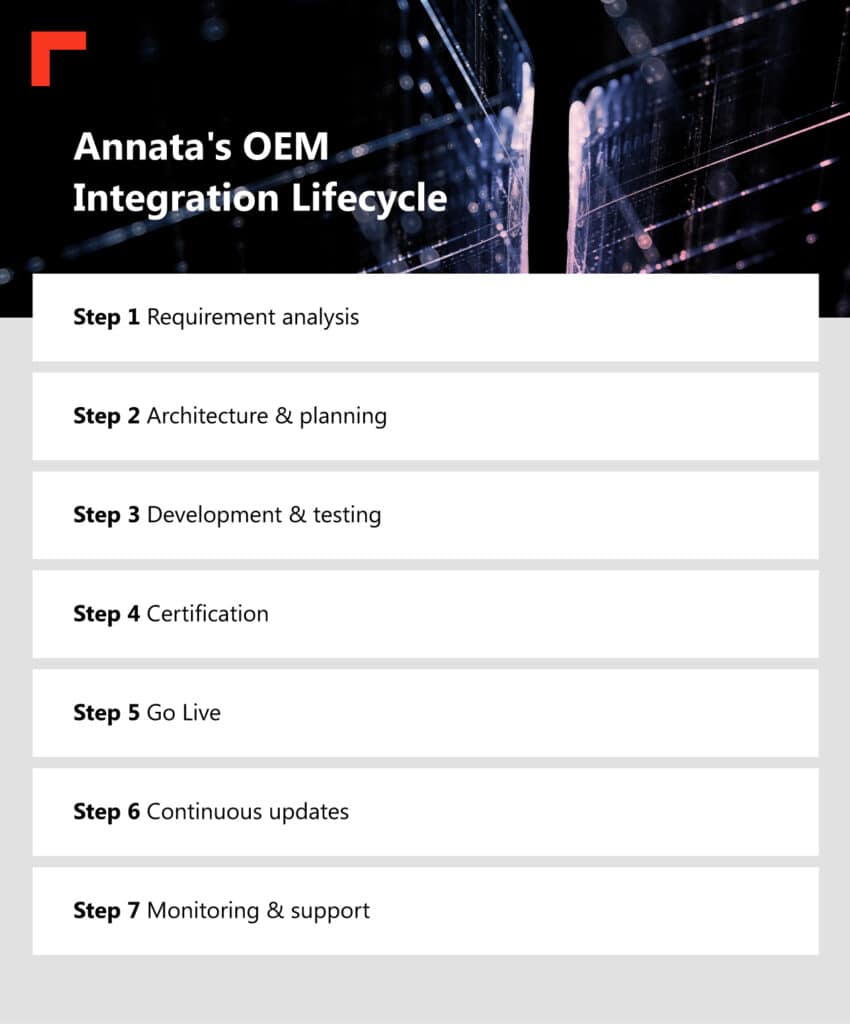

We follow a structured lifecycle that makes OEM integrations more predictable and easier to manage. It looks like this:

- Requirement analysis: We begin by identifying the key integration points and system needs.

- Architecture and planning: We define a blueprint for how the integration will connect seamlessly across platforms.

- Development and testing: We configure and build the solution, followed by rigorous testing for compatibility and performance.

- Certification: We align the integration with OEM standards and support the collaborative approval process.

- Go live: We deploy the solution and ensure a smooth transition into day-to-day use.

- Continuous updates: We provide ongoing updates, version upgrades, and bug fixes to stay aligned with evolving industry standards.

- Monitoring and support: We track the system’s health with proactive alerts and offer long-term maintenance for stability

Because A365 is built on modern Microsoft technology, the whole process is easier to scale and adapt. This is a big contrast with legacy systems, which often rely on point-to-point connections that are expensive to maintain and prone to breaking when standards change.

Q5. Could you share what makes Annata’s OEM integrations modular, adaptable, and future-ready compared to traditional methods?

Legacy systems often require one-off connections that are slow to develop and costly to maintain.

Working with Semler and Møller Mobility Group has been a real highlight. Their commitment to supporting dealer networks and deep knowledge of dealer operations made these projects especially rewarding.

What stood out most was seeing firsthand just how essential OEM integrations are to a business. Without them, dealers struggle with duplicate data entry, errors, and delayed reporting, all of which directly impact profitability and customer satisfaction. By connecting seamlessly with Volkswagen Group’s systems, these integrations eliminate those friction points and allow the dealer network to focus on delivering value to customers instead of wrestling with data.

On top of that, A365 brings embedded AI capabilities that go beyond what most competitors offer. Instead of being an add-on, AI is built into the platform, helping dealers reduce repetitive tasks and unlock efficiencies across sales, service, and reporting.

Q7. Annata has built a number of certified Volkswagen integrations. How many are there today, and what does this mean for businesses?

We have developed more than 20 certified integrations for VW Group, which is one of the most complex OEMs in the industry. These span sales, marketing, aftersales, and maintenance.

Our work with VW Group also includes proof-of-concept projects like Order Management (ORMA) and One Connect Workplace (OCW). These initiatives are designed to improve connected car management and workshop continuity, helping dealers boost telematics capabilities and efficiency.

Q8. Beyond Volkswagen, what’s next in the pipeline?

We’re currently working on new OEM integration requirements across our three focus industries: automotive, trucks and buses, and equipment. That includes projects with Mercedes-Benz, Daimler Truck, and Caterpillar. Each one has its own unique challenges, but our scalable team of consultants and analysts has the experience and resources to deliver quickly and to a high standard.

Q9. Looking at the industry more broadly, has anything changed in recent years in how OEM integrations are approached?

Yes, quite significantly. For more than 20 years, OEM integrations often relied on legacy text files that were difficult to maintain. Today, the focus has shifted to API-driven technology, connected vehicles, and AI-powered processes.

This shift allows for real-time data, smarter decision-making, and a much better customer experience. The pace of change is fast, but the opportunities it creates are even greater.

Q10. If you had to sum up the value Annata brings to Volkswagen dealers and partners in one sentence, what would it be?

Having all the essential importer and retailer integrations ready to use, combined with our unique relationship with VW Group, makes Annata the ideal partner to help modernize and future-proof VW businesses. Beyond integrations, our strength lies in our people, most of our team comes directly from the industry, so we genuinely understand dealer and importer challenges.

A365 itself was built by listening to our customers rather than forcing a one-size-fits-all solution, and we continue to evolve it in an evergreen way, ensuring the platform is always current and never outdated. We invest more than 30% of our revenue back into R&D, with dedicated prototype labs exploring AI and new digital technologies, so our customers can be confident they’re supported by a partner committed to innovation and long-term success.

Phil’s take makes it clear that OEM integrations are no longer just technical add-ons, they’re the backbone of how modern automotive, equipment, and mobility businesses run. With Annata’s A365 OEM integrations, companies can cut through complexity, unlock real-time insights, and create smoother experiences across the entire value chain.

This isn’t just about connecting systems. It’s about future-proofing your business.

Want to dive deeper? Connect directly with Phil Hart on LinkedIn and continue the conversation

Ready to explore your integration journey? Reach out to us to learn how we can help you build seamless OEM integrations that set your business up for long-term success.