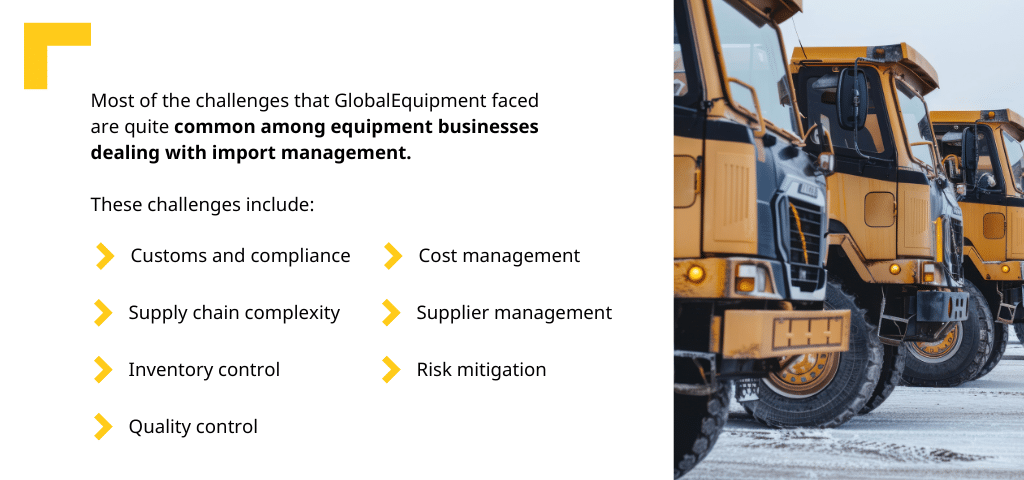

Imagine a thriving equipment company, GlobalEquipment Inc., that prides itself on delivering top-notch equipment to clients around the world. Their import management process is vital to their success, but recently, they’ve been struggling with a series of challenges.

From customs delays and compliance issues to inventory mismanagement and escalating costs, GlobalEquipment’s import operations are facing a tough time. As their frustration grows, they realize that they need a more efficient solution to turn the tide.

The import management struggle

GlobalEquipment Inc. started its day, as usual, dealing with a mountain of import-related paperwork. Customs regulations had become increasingly complex, and they were struggling to keep up with compliance requirements. Each shipment faced delays due to missing documents, and their financial management system failed to provide accurate cost tracking.

The team at GlobalEquipment also faced issues with inventory control. Their warehouses were either overstocked or faced shortages, which affected their ability to meet customer demands promptly.

Their suppliers, while reliable, were difficult to coordinate with, leading to further delays and misunderstandings. On top of that, the quality of some imported equipment was falling short of their high standards, resulting in costly returns and rework.

Supply chain complexity: Managing a global supply chain involves coordinating with multiple stakeholders, including suppliers, logistics providers, and customs authorities. This complexity can lead to inefficiencies and communication breakdowns.

Inventory control: Keeping track of inventory levels across different locations and stages of the import process is crucial for maintaining optimal stock levels and avoiding shortages or overstocking.

Quality assurance: Ensuring that imported equipment meets quality standards and specifications is vital for maintaining customer satisfaction and avoiding costly returns or rework.

Cost management: Importing equipment involves various costs, including transportation, tariffs, and handling fees. Effective cost management is essential for maintaining profitability.

Supplier management: Building and maintaining strong relationships with suppliers is crucial for securing favorable terms and ensuring reliable delivery of equipment.

Risk mitigation: Identifying and managing potential risks associated with the import process, such as delays, defects, or compliance issues, is key to safeguarding your operations.

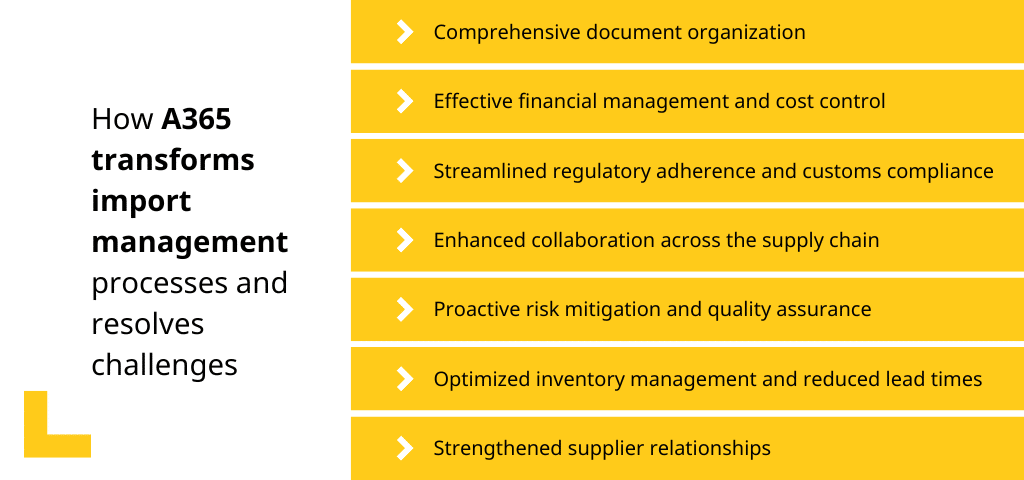

Transforming import management operations with A365

Recognizing the need for change, GlobalEquipment decided to implement a business solution tailored to the needs of the equipment industry.

Enter A365, a comprehensive solution that transforms how equipment businesses handle import management. Built on Microsoft Dynamics 365, alongside Azure, Power Platform, Copilot, and Dataverse, A365 ensures seamless integration, top-notch security, and user-friendly self-service options. With AI and Annata’s deep industry expertise at its core, A365 transforms operations by breaking down silos, optimizing supply chains, and enhancing decision-making.

A365’s import management is an all-encompassing tool that addresses every facet of the import process. From the moment an order is placed to the time it arrives and is integrated into inventory, A365 provides comprehensive support.

Comprehensive document organization

One of the first benefits GlobalEquipment experienced was the streamlined document organization. A365 centralized all documents, including invoices, shipping documents, and customs declarations. This feature allowed the team to easily access and manage essential paperwork, reducing errors and ensuring compliance. No more scrambling through files or worrying about missing documents—everything was neatly organized and readily available.

Effective financial management and cost control

With A365’s robust financial management tools, GlobalEquipment could now track and control costs with precision. The platform provided detailed insights into transportation fees, tariffs, and handling charges, helping the team stay within budget and identify areas for cost savings. This not only improved their financial management but also contributed to better overall profitability.

Streamlined regulatory adherence and customs compliance

Navigating complex regulations was no longer a hurdle for GlobalEquipment. A365’s tools for regulatory adherence ensured that all documents were in order and compliant with international standards. This proactive approach significantly reduced the risk of non-compliance and the associated penalties, allowing GlobalEquipment to focus on growing its business rather than dealing with regulatory issues.

Enhanced collaboration across the supply chain

A365 fostered better communication and collaboration between GlobalEquipment and its global partners. By providing a centralized platform for information sharing, the team could easily coordinate with suppliers, logistics providers, and customs authorities. This enhanced collaboration helped streamline the process, resolve issues more quickly, and ensure smooth operations.

Proactive risk mitigation and quality assurance

With A365, GlobalEquipment could proactively manage risks associated with the process. The platform’s risk mitigation tools helped identify potential issues early, while its quality assurance features ensured that all imported equipment met the company’s high standards. This resulted in fewer defects, reduced returns, and improved customer satisfaction.

Optimized inventory management and reduced lead times

A365’s inventory optimization tools provided GlobalEquipment with real-time visibility into stock levels, helping them avoid shortages and overstocking. By streamlining the import process, A365 also contributed to reduced lead times, ensuring that equipment was available when needed and improving overall operational efficiency.

Strengthened supplier relationships

Building and maintaining strong relationships with suppliers became easier with A365. The platform’s supplier relationship management features facilitated better communication and collaboration, helping GlobalEquipment secure favorable terms and ensure reliable delivery of equipment.

The benefits of A365: A new era of import management

By implementing A365, GlobalEquipment Inc. not only resolved its import management challenges but also experienced several key benefits:

Streamlined operations: A365’s comprehensive import management features streamlined GlobalEquipment’s entire import process, reducing complexity and improving operational efficiency. The centralized platform made managing imports more straightforward and less time-consuming.

Improved compliance: A365’s tools for regulatory adherence and customs compliance ensured that GlobalEquipment met all international standards and requirements, minimizing the risk of penalties and operational disruptions.

Enhanced efficiency: The platform’s focus on collaboration and communication improved efficiency across the supply chain. GlobalEquipment was able to resolve issues more quickly and keep its import operations running smoothly.

Cost savings: With effective financial management and cost control features, A365 helped GlobalEquipment stay within budget and identify opportunities for cost savings, contributing to improved profitability.

Risk management: A365’s risk mitigation tools allowed GlobalEquipment to proactively manage potential risks, ensuring that their equipment met quality standards and safeguarding their operations.

Better inventory management: Real-time visibility into inventory levels and optimized inventory management tools helped GlobalEquipment maintain optimal stock levels, avoid shortages, and improve overall efficiency.

For GlobalEquipment, and other companies like it, adopting A365 could mean the difference between constantly battling challenges and smoothly sailing through them. A365 not only addresses their current pain points but also equips them with the tools needed to anticipate and adapt to future challenges

If you’re facing similar challenges with your equipment import management, consider how A365 can help streamline your processes and drive operational success.

Contact us today to learn more about how A365 can transform your import management and support your business growth.