Import management often plays the understated role that holds the key to seamless supply chain orchestration in automotive operations. Yet, it remains an often-missed critical area, overshadowed by more visible concerns.

This oversight of import management in automotive businesses stems from a combination of factors, including a focus on core operations, perceived complexities, and a lack of immediate visibility into its benefits. As the automotive industry evolves, recognizing and addressing these challenges will be essential for sustained growth and competitiveness.

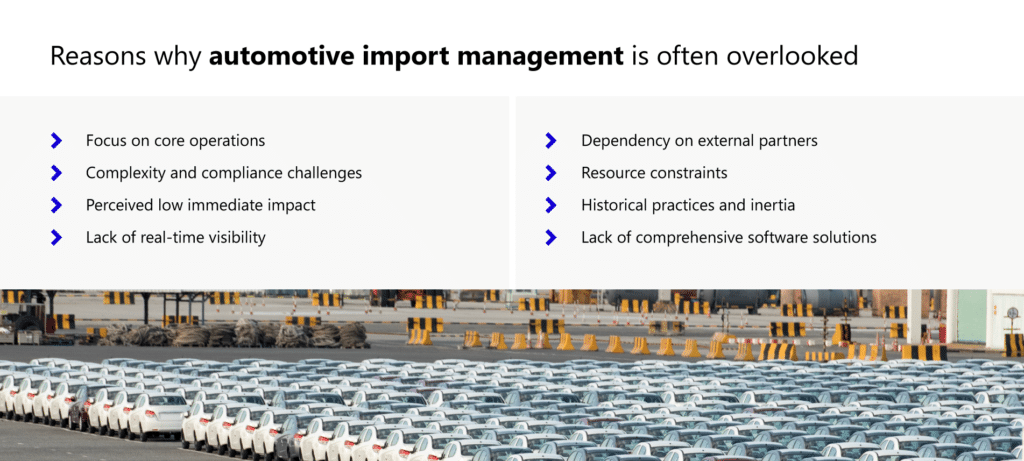

Reasons why automotive import management is often overlooked

Focus on core operations: Prioritization of core functions like manufacturing and sales often sidelines the nuanced realm of import management.

Complexity and compliance challenges: The intricate landscape of international trade regulations can be daunting, leading businesses to shy away from delving into import management due to perceived complexity.

Perceived low immediate impact: Immediate benefits of effective import management, such as cost savings and supply chain efficiency, may not be readily apparent, leading to its oversight.

Lack of real-time visibility: A deficiency in real-time visibility into the supply chain, including shipments and compliance statuses, contributes to the neglect of import management.

Dependency on external partners: The reliance on external partners may foster an assumption that import management is effectively handled externally, reducing internal oversight.

Resource constraints: Limited resources, especially in smaller businesses, may hinder the allocation of time and manpower to optimize import management processes.

Historical practices and inertia: A resistance to change or the perception that existing practices suffice can perpetuate the oversight of import management.

Lack of comprehensive software solutions: The absence of suitable technology solutions may impede the implementation of efficient import management practices, contributing to neglect in this crucial aspect of operations.

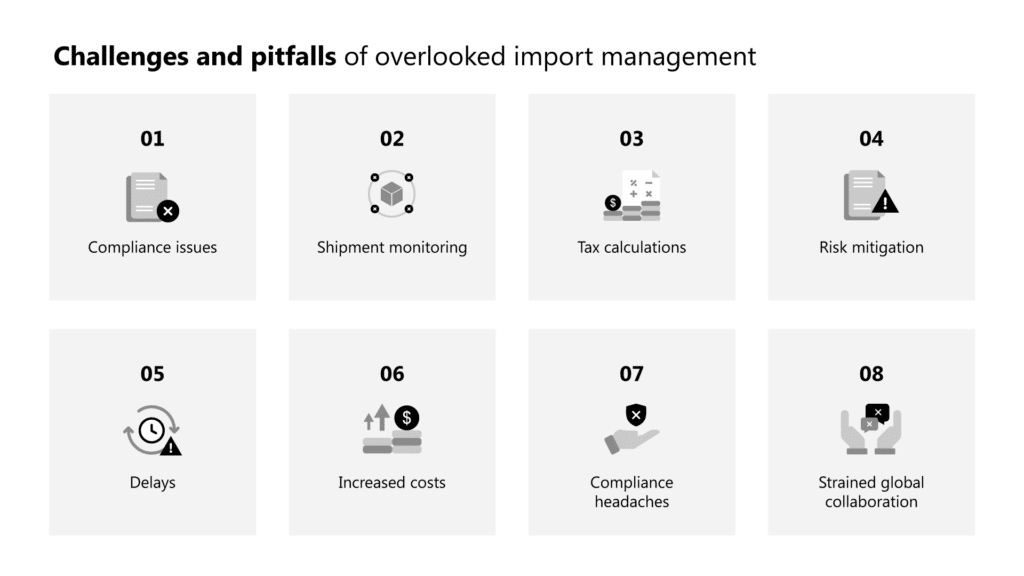

Challenges and pitfalls of overlooked import management

In the vast expanse of automotive operations, import management is a labyrinth of challenges waiting to be navigated. Neglecting these aspects can result in delays, fines, and reputational damage for automotive businesses.

Additionally, the lack of real-time visibility into shipments, imprecise duty and tax calculations, and insufficient risk mitigation strategies can further compound the challenges, leading to increased costs and operational inefficiencies.

Compliance issues: Failure to align with evolving international trade regulations can lead to fines, delayed shipments, and reputational damage.

Shipment monitoring: Inadequate real-time visibility may result in production delays, increased costs, and missed delivery deadlines.

Tax calculations: Miscalculating duties on imports can trigger financial repercussions, affecting budgetary planning and leading to disputes.

Risk mitigation: Without a proactive risk strategy, geopolitical uncertainties and transportation mishaps can disrupt the supply chain.

Delays: Import-related delays can halt production, increasing holding costs and compromising revenue opportunities.

Increased costs: Inefficient import processes contribute to higher operational expenses, eroding profit margins.

Compliance headaches: Neglecting global trade compliance may lead to regulatory nightmares, audits, fines, and customs clearance delays.

Strained global collaboration: Lack of visibility and transparency hampers effective communication, straining relationships with international partners.

Seamless import management from beginning to end with A365

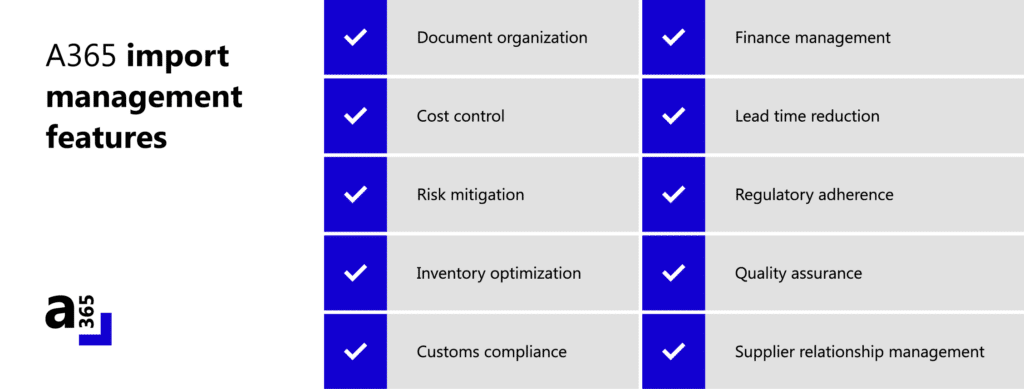

A365‘s import management feature is an all-encompassing tool that addresses every facet of the import process. It provides comprehensive support, simplifying the import process and ensuring compliance with international operating standards.

The platform promotes efficient communication between your management teams and global partners, streamlining international collaboration and ensuring smooth import operations.

Warranty management and maintenance processes are elevated, enhancing the value of each imported item and ensuring exceptional after-sales experiences. Import operations can experience minimized downtime, as A365 is meticulously designed to ensure peak operational efficiency, making sure your vehicles and assets are always available when needed.

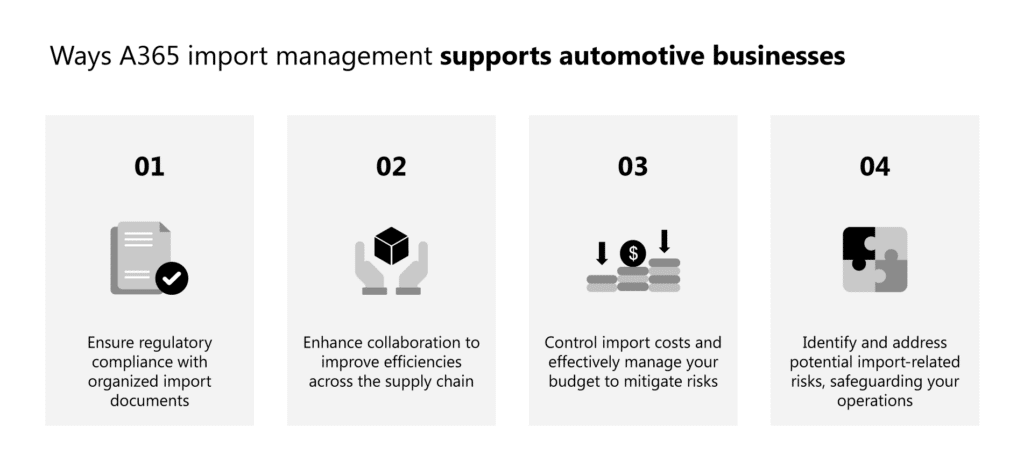

Ways A365 import management supports automotive businesses

Ensure regulatory compliance with organized import documents:

Scenario: An automotive manufacturer is importing a new line of electric vehicles. Without proper documentation organization, they face customs clearance delays due to missing certificates of compliance. A comprehensive import management system like A365 ensures all required documents are in order, facilitating smooth customs clearance and preventing regulatory hiccups.

Enhance collaboration to improve efficiencies across the supply chain:

Scenario: A multinational automotive company sources components from various suppliers globally. Inefficient communication leads to delays in production, as suppliers are unaware of changes in demand. A365’s collaborative features enable real-time communication, fostering transparency across the supply chain. This ensures timely adjustments to production schedules, enhancing overall efficiency in the import process.

Control import costs and effectively manage your budget to mitigate risks:

Scenario: A car manufacturer struggles with unpredictable import duties, impacting their budget for a new model launch. With A365’s duty and tax calculation features, the company can accurately forecast import costs, allowing for effective budget management. This proactive approach mitigates financial risks, ensuring the project stays within budget constraints.

Identify and address potential import-related risks, safeguarding your operations:

Scenario: A global automotive supplier faces potential disruptions due to a sudden change in trade regulations affecting their import routes. The company may experience delays and increased costs without a system to identify such risks. A365’s risk management tools analyze data to identify potential risks, allowing the company to implement contingency plans, safeguarding its import operations from unforeseen challenges.

Our import management functionalities embedded in A365 seamlessly integrate with other Microsoft technologies, such as Microsoft Azure for cloud services and Microsoft Power Platform for data analytics and workflow automation. This enables the full leveraging of the Microsoft ecosystem, ensuring a comprehensive and cohesive solution for your import operations.

A365 harnesses the transformative power of AI within Microsoft Dynamics 365 to redefine import management. Through AI-driven insights and personalized interactions, A365 fine-tunes import processes, identifies efficiencies, and streamlines workflows, resulting in heightened performance and operational excellence.

The predictive intelligence of AI equips your import needs with confidence and foresight. By analyzing data and user patterns, AI-driven import forecasting becomes the cornerstone of your import operations. This predictive capability empowers your business to excel in the import of vehicles, enabling informed decisions and the efficient orchestration of import workflows.

In conclusion, import management is a critical need that, when ignored, can lead to a host of challenges for automotive businesses. A365, with its comprehensive suite of import management features, not only addresses these challenges but transforms them into opportunities for growth.

Elevate your automotive business by gaining full control over the supply chain, ensuring compliance, and fostering global collaboration through the power of A365. Embrace a future where import management is not just a necessity but a strategic advantage in the competitive landscape of the automotive industry. Connect with us today!