In the automotive, trucks & buses, and equipment industries, managing parts and accessories inventory is becoming more complex and critical than ever. With supply chains in flux and the demand for real-time data and seamless integrations skyrocketing, businesses need smarter, more efficient solutions to stay competitive. That’s where the real innovation is happening and we felt it was essential to dig deeper into this hot topic.

To do so, we sat down with József Pósfai, our Parts & Accessories Inventory Product Owner at Annata, who’s leading the charge on transforming the way businesses handle parts and accessories inventory. With a background in consulting and R&D, József has seen firsthand how the industry is evolving.

In this conversation, he walks us through how Annata’s approach to Parts & Accessories Inventory Management is streamlining operations, improving efficiency, and tackling the unique challenges faced by companies in these sectors. From automating data processing to enhancing A365 with Microsoft D365 Finance & Operation’s capabilities, József shares his insights on how these innovations are shaping the future of inventory management.

Let’s dive right in.

1. Let’s start with your journey. How did you find your way into the world of product ownership, and what led you to your current role at Annata?

Well, it was quite a roller coaster with a home run, to be honest. Before Annata, I started my Dynamics endeavour as a consultant almost 13 years ago and quickly became a functional area lead and a team leader of an R&D team, focusing on logistics implementations. However, professional work was something I favoured as opposed to managing a rather big team, so I decided to go back to the frontline. I joined Biztup Hungary (acquired by Annata) in 2017 and continued my journey as a consultant here.

I worked on various project implementations as a consultant for a couple of years, but later, some bells started to ring inside me. I felt the urge to take a U-turn and go back to R&D. Solution design is really my cup of tea, so becoming the product owner of the recently established Parts & Accessories Inventory Management R&D team can be considered a homecoming for me.

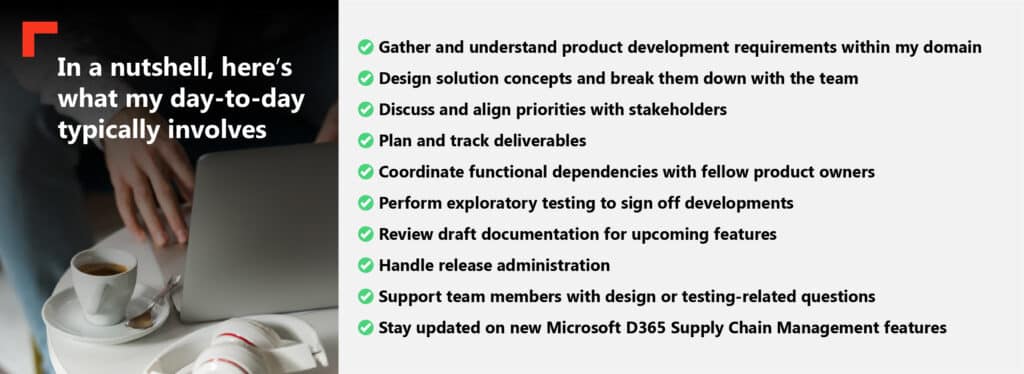

2. What does a typical day look like for you as the Product Owner for Parts & Accessories Inventory Management? Any routines or responsibilities that anchor your day?

We operate using the Scrum framework, which gives us some cornerstones during our day-to-day operations. We usually start our mornings with a daily Scrum meeting, where the team discusses the progress of ongoing work.

Even though the ceremonies are the same, the topics we discuss constantly change, depending on what’s currently on our plate. Don’t get me wrong. This is a positive thing for me. I personally seek new challenges in my professional life.

Because of this, I don’t really have a fixed daily routine. I prioritize my tasks dynamically, based on urgency, and focus on resolving bottlenecks as soon as possible.

3. What excites you most about working on this part of the A365 solution?

I was always keen on delivering business value, and I see how valuable A365 is. It motivates me to contribute to this solution by adding more business value within my area. This is what gives me the most in my position.

4. For those unfamiliar, how would you describe what the Parts & Accessories Inventory Management solution in A365 does?

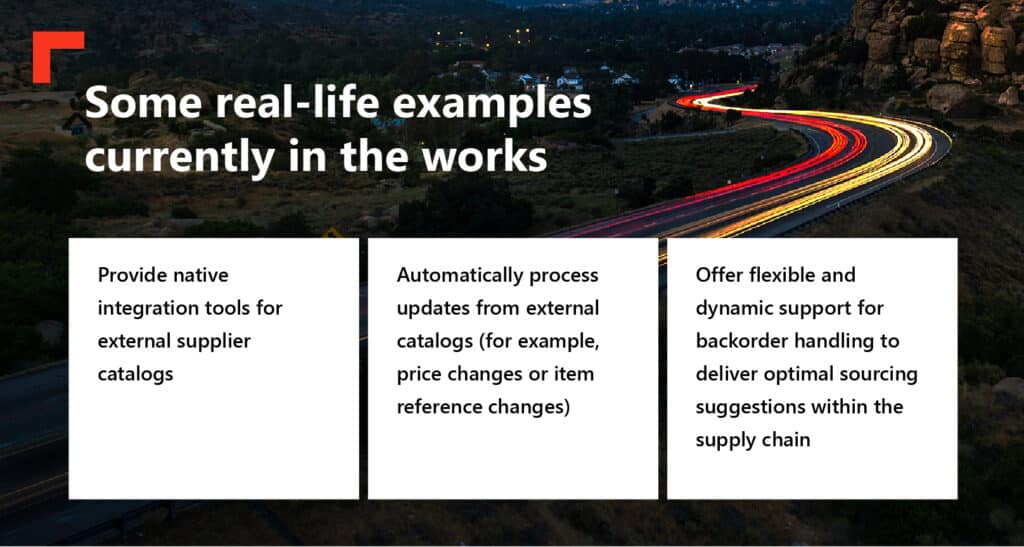

Parts & Accessories is currently being enhanced in several areas to tailor our solution stack to specific industry needs. But the main motive behind each and every step we take is to provide an additional layer on top of the standard Microsoft D365 Finance and Operations, which, on its own, is already quite rich in terms of functionality. Our goal is to help customers benefit beyond what the standard solution can offer.

This includes enhanced master data management (like a shared external item catalog and supplier items), price management, item supersession handling, and improvements to order orchestration within the supply chain of dealers and importers.

At the same time, we also need to stay aware of the direction Microsoft is taking with product development so that we remain compatible with any upcoming features being added to the base product.

So, I would describe our domain as a triangle; the space we work in is defined by these three cornerstones:

5. What kinds of real-world challenges does this parts solution help automotive, trucks & buses, and equipment businesses solve?

The biggest real-world challenge we face is that changes in information, such as prices, inventory, and other supply chain data, are more turbulent than ever. Because of this, we need to enable our users to process these changes in the most automated way possible. Speeding up data processing helps accelerate decision-making and the physical processes that follow.

Our goal is to support parts-related processes in shifting into higher gears by providing a flexible backbone within A365 Finance and Operations.

6. There are plenty of inventory systems out there. In your view, what makes Annata’s approach stand out from the rest?

Most inventory systems require a lot of development to connect them with ERPs in order to sync inventory levels and ensure consistency between physical and financial processes.

Fun fact, and quite a contradiction, actually, ERPs were originally designed for inventory tracking purposes. You can also see that standard D365 Supply Chain Management already has a lot of features that support inventory handling quite well.

Our advantage is that we are building directly on this foundation within F&O, without the hurdle of creating fragile integration or synchronization routines between a satellite system and the ERP.

7. How does the solution integrate with other parts of A365 to create a unified flow of information?

The Parts area goes hand in hand with Service. In other words, Service is usually the biggest internal consumer of parts, so we have to make sure that we develop A365 F&O in a way that supports transactions originating from servicing requirements.

8. Looking ahead, what trends or challenges do you think will have the biggest impact on parts inventory management in the years to come?

Traditional B2B (business-to-business) companies have slowly begun stepping into the B2C (business-to-consumer) market in the hope of gaining more customer insights. These insights can help them tailor and shape their operations in a more time- and cost-effective way.

This shift is a challenge, as it requires them to enter unfamiliar territory such as multi-channel order handling, more granular distribution and transportation management, and proper inventory traceability.

On top of that, international trade has become increasingly turbulent. Constantly changing duty tariffs, global supply chain disruptions, and growing pressure to make dynamic sourcing decisions are all part of the landscape.

9. When it comes to deciding what to build next, how do you and your team prioritize improvements or features? Is it feedback-driven, data-led, or a mix of both?

We already have a list of ideas and requirements coming from our stakeholders, which we are gradually trying to synthesize into our new solution to create a unified path forward.

In other words, we are currently reshaping our Parts solution in A365. And while we have a roadmap for our journey with some key milestones, we still need local guides to help us maximize value and make the journey as impactful as possible.

Since customers know best which features bring the greatest business value, we’re always happy to receive relevant feedback and ideas from them at any stage of the roll-out of our new features.

10. And finally, are there any tools, frameworks, or even books that have shaped how you approach product ownership or think about building smarter inventory solutions?

Tools and frameworks are useful, but my two cents on this is that it’s more important to know your industry specifics and business needs as well as possible. I would say it’s better to take your time and understand yourself and your challenges first, before jumping into implementing fancy solutions using popular frameworks without a clear insight into how compatible they actually are with your needs and goals.

About József Pósfai

József Pósfai brings over 13 years of experience in the Dynamics space, with a strong focus on logistics and R&D. Starting his career as a consultant, he quickly advanced to leading teams and functional areas. After a few years in management, he returned to consulting and joined Annata Hungary in 2017, where he later took on the role of Product Owner for the Parts & Accessories Inventory Management team.

In this role, József leads the development of Annata’s solutions built on Microsoft D365, improving key areas like master data management, price management, and order orchestration. His goal is to deliver tangible business value by automating processes and enhancing efficiency in parts and inventory management for industries such as automotive, trucks, buses, and equipment.

József’s approach is centered on understanding the core challenges and delivering solutions that truly make a difference, ensuring Annata’s products stay aligned with evolving industry needs and Microsoft’s roadmap.

To learn more about our A365 solution capabilities, reach out to us for a personalized demo.