As the gears of modern civilization churn, equipment, and heavy machinery stand as the backbone of numerous sectors. Yet, behind the steel behemoths and earth-shattering capabilities lies a landscape of challenges that test the mettle of these equipment businesses.

They face a plethora of challenges when it comes to managing their operations efficiently. From complex supply chains to tedious maintenance processes, the sheer intricacy of these businesses can often lead to inefficiencies, delays, and increased costs.

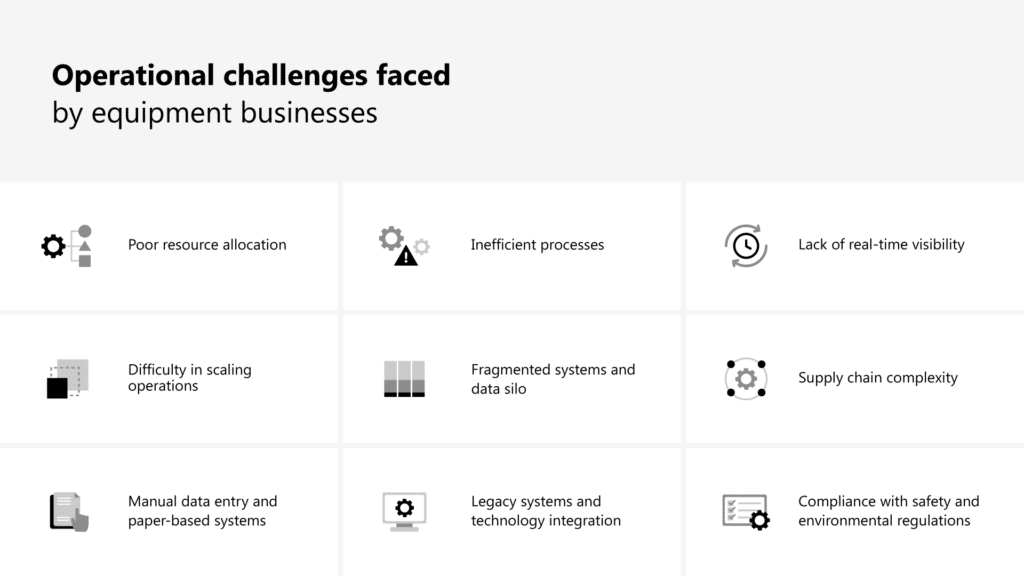

Operational challenges faced by equipment businesses

1. Poor resource allocation

Inefficient allocation of financial, human, and material resources can lead to increased costs and reduced productivity. Overinvesting in one area while neglecting others can cause imbalances and hinder overall operational efficiency.

It may result in underutilized equipment or an inadequate workforce, leading to missed opportunities and lower profitability. Additionally, it can impact customer service, as the inability to meet demands promptly affects satisfaction levels.

2. Inefficient processes

Inefficient processes pose significant challenges for equipment businesses, causing reduced productivity, higher costs, longer lead times, and delays in delivering products or services. This impacts product quality, customer satisfaction, and scalability.

Employee morale can suffer due to frustrating processes, leading to potential turnover. Competitively, inefficient businesses may struggle against more efficient rivals.

3. Lack of real-time visibility

The lack of real-time visibility poses significant challenges for equipment businesses. Without up-to-date insights, decision-making becomes difficult, leading to higher maintenance costs and customer service issues.

Optimizing workflows and adapting to market demands become harder, affecting efficiency and competitiveness.

4. Difficulty in scaling operations

As demand increases, inefficient processes and outdated technologies may hinder expansion while inadequate infrastructure, lack of skilled labor, and limited access to resources can further impede growth. Additionally, complex supply chains and regulatory requirements may create barriers to entering new markets or regions.

Scaling also necessitates significant investments in machinery, facilities, and logistics, which can strain financial resources. Without proper planning and flexibility, businesses may struggle to meet growing demands, maintain quality standards, and deliver products/services efficiently.

5. Manual data entry and paper-based systems

Relying on manual processes leads to errors, delays, and increased administrative burden. Data entry mistakes can impact decision-making and lead to inefficiencies. Using paper-based systems increases the risk of data loss and makes information retrieval time-consuming.

A lack of real-time insights hinders proactive maintenance and planning. Additionally, paper-based documentation is harder to share and collaborate on, affecting communication and teamwork.

6. Fragmented systems and data silo

When different departments use separate software or systems that do not communicate with each other, it leads to inefficiencies and data discrepancies. Information is trapped in isolated silos, hindering collaboration and decision-making.

This lack of integrated data visibility results in suboptimal resource allocation, poor customer service, and hindered operational efficiency. Gaining a holistic view of the business and identifying opportunities for improvement also becomes a challenge.

7.Supply chain complexity

As they rely on multiple suppliers for raw materials, components, and parts, any disruptions or delays in the supply chain can cause production bottlenecks and increase lead times. Coordinating with numerous suppliers can be logistically challenging and result in communication gaps, affecting overall efficiency.

Global supply chains may be subject to geopolitical or economic uncertainties, impacting sourcing and distribution. This makes maintaining optimal inventory levels to balance demand and supply tricky.

8. Legacy systems and technology integration

Outdated technology can hinder operational efficiency, limit automation, and lack compatibility with modern solutions. Integrating new technologies with existing systems is complex, often leading to data discrepancies and errors.

Legacy systems may also be more vulnerable to security threats, putting sensitive information at risk all while having hefty maintenance costs.

9. Compliance with safety and environmental regulations

Equipment businesses must adhere to stringent laws to ensure the safety of their workforce, customers, and the environment. Failure to meet these standards can result in legal penalties, damaged reputation, and potential shutdowns.

Keeping up with evolving regulations, obtaining necessary certifications, and implementing safety protocols can be complex and time-consuming. Most times, equipment businesses face unique compliance requirements based on the specific industry they serve.

Taking your equipment business processes from complexity to simplicity

With complex supply chains involving suppliers, manufacturers, and distributors, coupled with the challenges of equipment maintenance and customer satisfaction, businesses often find themselves overwhelmed and burdened with manual tasks and disjointed systems. This is where Annata steps in as a trusted partner to integrate and simplify these processes.

Annata is revolutionizing equipment business operations by transforming complexity into simplicity. Annata understands the unique needs and pain points of equipment businesses. This is why our cloud business solution is designed to streamline end-to-end processes, from the supply chain to the end user.

Annata empowers equipment businesses to achieve simplicity organization-wide. By leveraging advanced technologies and industry expertise, Annata enables companies to optimize their supply chain, automate workflows, access real-time analytics, and enhance customer experiences.

The result? Streamlined processes, reduced complexities, increased productivity, and ultimately, improved profitability.

A must-have solution to simplify equipment business processes

The A365 innovative cloud-based solution is built on the robust foundation of Microsoft Dynamics 365 and other cutting-edge Microsoft technologies, tailored specifically to address the unique pain points faced by equipment businesses. Leveraging the power of Microsoft’s ecosystem, A365 delivers a comprehensive and integrated platform that streamlines operations, enhances efficiency, and drives business success.

A365 inherits the scalability, reliability, and security of one of the world’s leading enterprise resource planning (ERP) systems. This ensures that it can handle the complex requirements of equipment businesses, which often deal with extensive supply chains, intricate inventory management, and diverse customer needs.

A365’s integration with other Microsoft technologies, such as Azure IoT and Power Platform, further amplifies its capabilities. With Microsoft Azure, equipment businesses can harness the potential of the Internet of Things (IoT), leveraging real-time data from connected devices to enable predictive maintenance and optimize equipment performance. Power BI facilitates advanced data analytics and visualization, empowering businesses to gain actionable insights and make data-driven decisions.

A365 offers a comprehensive toolkit that equips heavy equipment businesses to face their challenges with confidence. From simplifying supply chain management to streamlining equipment maintenance and service, A365 automates workflows, reduces manual efforts, and enhances collaboration across teams. Its centralized data management eliminates data silos and enhances visibility, enabling better decision-making.

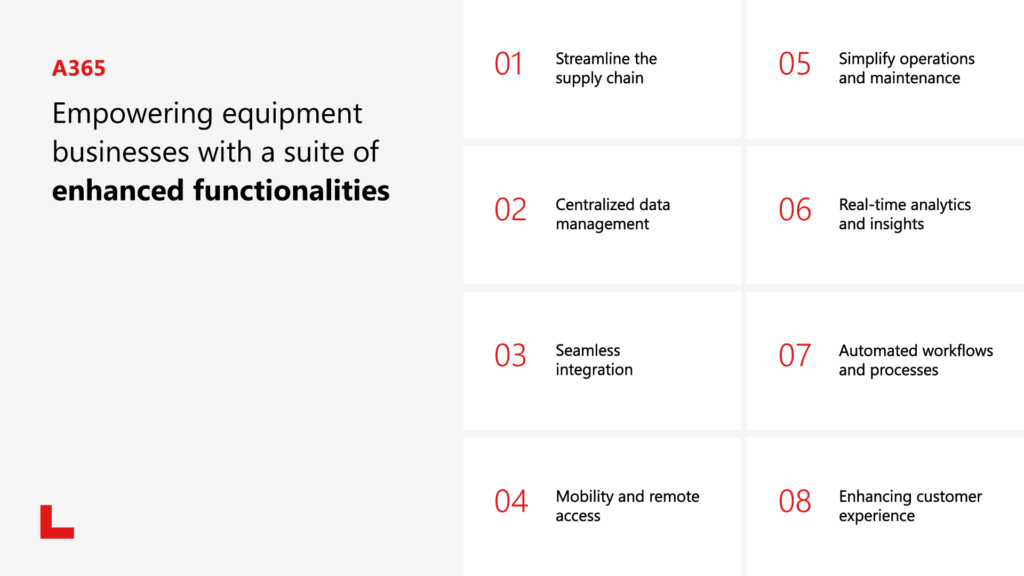

A suite of enhanced functionalities for equipment businesses

- Streamline the supply chain

A365 enables seamless integration across the supply chain, connecting suppliers, manufacturers, distributors, and customers. This unified approach simplifies procurement, optimizes inventory management, and provides enhanced visibility into the entire supply chain network.

By streamlining communication and data flow, A365 ensures more efficient and well-coordinated operations, allowing businesses to make informed decisions and respond promptly to market demands and challenges.

2. Simplify operations and maintenance

With A365, equipment maintenance, repairs, and service management become seamless processes. Automated scheduling ensures timely service appointments, while predictive maintenance anticipates potential issues, preventing costly breakdowns. Technicians benefit from mobile accessibility, enabling them to access critical information on the go.

This streamlined approach improves maintenance efficiency, reduces downtime, and increases equipment reliability. As a result, equipment businesses can enhance customer satisfaction, optimize resources, and achieve greater operational excellence with A365’s cutting-edge features.

3. Centralized data management

By integrating multiple functionalities into one cohesive system, A365 eliminates the burden of using disparate systems. This consolidation simplifies data entry, updates, and retrieval processes, resulting in a more efficient and streamlined workflow.

With all data accessible within a single platform, employees can swiftly access and analyze information without the need to navigate through various software applications. A365’s unified approach fosters better collaboration, reduces errors, and enhances productivity, enabling equipment businesses to focus on core operations and achieve greater simplicity in their day-to-day tasks.

4. Real-time analytics and insights

Its user-friendly data analysis and visualization tools simplify the process of extracting valuable information from complex datasets. With this capability, businesses can identify trends, anticipate market shifts, and optimize their operations effectively.

Proactive issue resolution becomes achievable as A365’s real-time insights enable businesses to address challenges before they escalate. Equipped with valuable data-driven knowledge, equipment businesses can make strategic decisions, improve efficiency, and stay competitive in a dynamic market landscape.

5. Seamless integration

A365 is designed with flexibility in mind, allowing seamless integration with existing or legacy solutions. Its adaptable architecture and Application Programming Interface (API) enable smooth data exchange and communication with other systems.

By integrating A365 with existing software, equipment businesses can preserve their current workflows and data while leveraging the advanced capabilities of A365. This integration ensures a cost-effective transition, enabling businesses to unlock the full potential of A365 while building upon their existing technology investments.

6. Automated Workflows and Processes

A365’s automation capabilities revolutionize equipment businesses by eliminating tedious manual tasks, saving valuable time and resources. Through automated workflows and processes, routine activities such as data entry, approvals, and notifications are streamlined, reducing the risk of human errors.

This not only accelerates operations but also enhances consistency and compliance. By freeing employees from repetitive tasks, A365 empowers them to focus on more strategic and value-added activities, leading to increased productivity and overall process efficiency within the organization.

7. Mobility and remote access

With A365’s mobility and remote access features, equipment businesses experience newfound flexibility and efficiency. Employees can access crucial business information, manage operations, and respond promptly to inquiries, even when on the go. This capability enables elevated field operations, empowering technicians to address issues remotely and expedite service delivery.

Quicker response times lead to improved customer satisfaction, while remote equipment management ensures optimal asset utilization. A365’s mobile accessibility revolutionizes the way businesses operate, providing a competitive edge and enhancing overall performance in a dynamic and fast-paced business landscape.

8. Enhancing customer experience

A365 streamlines sales processes by offering personalized interactions. Personalized interactions enhance customer engagement and satisfaction, as sales representatives can tailor their approach based on individual preferences and needs.

With A365’s sales optimization features, equipment businesses can foster stronger customer relationships, improve sales efficiency, and deliver a seamless and user-centric buying experience.

Ponsse- Achieving equipment simplicity with A365

Headquartered in a small village called Vieremä, Finland, Ponsse is one of the world’s leading manufacturers of cut-to-length forest machines. The company was founded in 1970 by forest machine entrepreneur Einari Vidgrén, and it has been a forerunner in cut-to-length logging throughout its history. Today Ponsse has customers across the Nordics, Europe, Asia-Pacific, and the Americas as well as about 30 dealers globally.

Ponsse aims to be the best solution provider and offer superior customer experience, not only by selling machines but also by selling solutions with the best cut-to-length machines in the world.

To support Ponsse’s goal, the Ponsse team wanted an ERP to handle processes for the company’s external stakeholders such as dealers and customers through APIs. Additionally, there were requirements for real-time data to be extracted to Microsoft Azure Data Platform and from there to be used for reporting, analytics, and digital applications running in the Microsoft Azure cloud.

Ponsse’s choice, as the new ERP, was Microsoft Dynamics 365 complemented by the annata365 designed for the manufacturing and distribution industry of equipment. The new ERP solution is being used for a number of things, such as material and stock management, procurement, sales, deliveries, fieldwork control and maintenance, invoicing, and financial management and reporting. The ERP solution is also used for aftersales processes, such as spare parts sales and maintenance.

Read the full customer story here.

Discover how A365 can help you revolutionize your equipment business processes here.