Imagine running your thriving equipment business, whether in construction, mining, agriculture, forestry, or material handling only to realize that competitors are pulling ahead while you struggle with inefficiencies, unexpected equipment failures, and customer dissatisfaction. The difference? They have embraced digital transformation for equipment businesses, while you’re still relying on outdated, manual processes.

In today’s fast-moving landscape, digital transformation isn’t a futuristic concept, it’s happening now. Businesses across the equipment industry, from distributors and importers to dealers, retailers, service centers, scrapyards, rental or leasing companies, and fleet operators, must adapt or risk being left behind. The journey to digital transformation for equipment businesses may seem overwhelming, but the cost of inaction is far greater.

Let’s explore the challenges businesses face, the consequences of delaying digital transformation, and the stark contrast between those who embrace change and those who don’t.

The challenges of digital transformation for equipment businesses

While digital transformation for equipment businesses promises efficiency, cost savings, and improved customer experiences, many businesses hesitate due to common roadblocks:

Legacy systems slowing down operations

Are you still using outdated software, disconnected databases, or even paper records? These slow decision-making, cause data inconsistencies, and create inefficiencies across departments. Managing inventory, sales, or maintenance with outdated systems leads to errors and wasted time.

Lack of real-time visibility

Data silos are a major problem. Sales, inventory, customer support, and maintenance teams often work in isolation, each with separate records. Without a centralized system, getting real-time insights into equipment availability, usage, and service history is nearly impossible. Poor forecasting and lost revenue opportunities follow.

Resistance to change

Employees and management might fear disruption or struggle with the learning curve of new technology. The shift from traditional processes to cloud-based platforms and automation can feel intimidating. However, the longer you wait, the harder it becomes to catch up.

High initial investment

Digital transformation requires investment in new technologies like Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Dealer Management System (DMS), Dealer Distribution Systems (DDS), and AI tools. The initial cost may seem daunting, but the long-term return through increased efficiency, reduced downtime, and better customer satisfaction far outweighs the expense.

Shortage of digital skills

Many industry employees are accustomed to manual processes and may lack experience with digital tools. Without proper training, businesses struggle to fully leverage new technologies.

Digital transformation for equipment businesses: The consequences of inaction

What happens when businesses resist digital transformation? Unfortunately, the risks are severe:

- Operational inefficiencies – Manual paperwork, disconnected systems, and outdated processes slow down operations, leading to delays and errors.

- Declining customer satisfaction – Customers expect quick responses, transparent pricing, and seamless service. Without digital tools, meeting these demands is nearly impossible.

- Lost revenue and shrinking margins – Inefficient operations, equipment downtime, and poor inventory tracking lead to increased costs and missed opportunities.

- Frequent equipment failures and high maintenance costs – Without predictive analytics, maintenance remains reactive, leading to unexpected breakdowns and costly emergency repairs.

- Falling behind competitors – Digitalized companies gain a major advantage through automation, data-driven decision-making, and superior customer service.

Before and after: Digital transformation for equipment businesses in action

To better understand the impact of digital transformation, let’s look at how businesses across different segments of the equipment industry perform before and after adopting digital solutions.

Before: The struggling equipment service center

A service center selling and servicing agricultural equipment relies on manual tracking for inventory and orders, leading to frequent stockouts and delays. Warranty claims take weeks to process because paperwork must be mailed and reviewed manually. Customers grow frustrated with slow service and look for alternatives.

After: The digitalized equipment service center

With an integrated digital platform, inventory updates in real time, allowing customers to check availability online. Orders and warranty claims are processed digitally, significantly reducing turnaround times. Automated reminders ensure customers never miss scheduled maintenance. Sales teams have instant access to customer histories, allowing them to provide personalized recommendations that boost revenue.

Before: The overwhelmed importer

An equipment importer manages thousands of products with outdated spreadsheets. Forecasting is inaccurate, leading to overstocked warehouses or critical shortages. The sales team struggles to provide up-to-date pricing and availability, and shipments are frequently delayed due to miscommunication.

After: The digitalized importer

With a cloud-based system, the importer gains full visibility into supply chains, automating demand forecasting and optimizing stock levels. Sales teams access real-time pricing and inventory, improving customer service and sales performance. Logistics are streamlined, ensuring on-time deliveries and reducing costs.

Stay ahead with A365 – Your trusted partner for digital transformation for equipment businesses

We get it. Digital transformation can feel overwhelming. Where do you even start? What if things go wrong? It’s a big shift, and you’re not alone in feeling unsure. That’s exactly why you need a trusted partner like Annata, relied on by some of the world’s leading equipment brands, including AB Equipment, Ponsse, and Hitachi Construction Machinery.

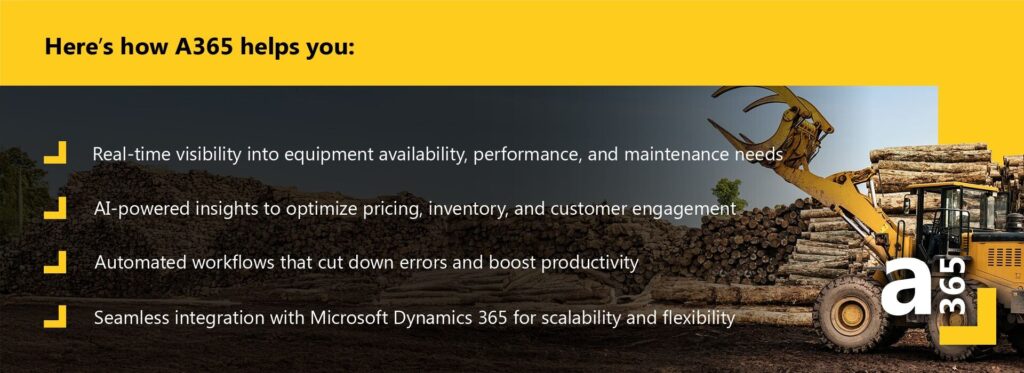

A365 is our cutting-edge, cloud-based solution tailored for the equipment industry. With A365, you don’t have to go all in at once. Start small with modular solutions and tackle one area at a time, whether it’s sales, service, rentals, inventory, or finance. And when you’re ready, you can scale up to the full platform. We’re here to guide you every step of the way.

A365 brings together everything you need in one seamless experience. It integrates ERP, CRM, DMS, and DDS into a single powerhouse solution that simplifies your workflows and boosts productivity.

A365 adapts to your business needs with AI-driven insights and IoT-enabled features, making it scalable, customizable, and ready for the future. From predictive maintenance to dynamic pricing strategies, A365 provides the tools you need to innovate and stay competitive, making digital transformation for equipment businesses a breeze.

The best part? A365 is continuously evolving to meet industry demands so you don’t have to stress about keeping up with new technologies or market changes. Our AI-driven platform adapts, learns, and improves, so you can focus on running your business.

And because A365 is built on Microsoft’s technologies like Microsoft Dynamics 365, Azure, Copilot, Power Platform, and Dataverse, you’ll always have a solution that’s secure, evergreen, and future-ready.

But what truly sets A365 apart? It’s not just designed by industry experts, some with decades of experience in the equipment sector. It’s also shaped by listening to our customers. Their real-world challenges and feedback drive continuous innovation so we can build solutions that actually work for you.

So, whether you’re an importer, distributor, dealer, service center, rental or leasing company, or fleet operator, we know what it takes to help you thrive.

Ready to take the next step? Let’s build your digital future together. Connect with us now.