If you run or work in an equipment business, chances are you’ve been there:

- A customer brings in a machine for trade-in.

- Your technician scribbles notes on a clipboard.

- Someone else enters the same notes into a system.

- A manager has to manually approve the findings.

- Days later, a service advisor calls the customer back with missing or outdated information.

By that time, the customer’s frustrated, your team’s confused, and nobody’s really sure whether the inspection was accurate in the first place.

Sound familiar?

If so, you’re not alone. Equipment inspections, whether for pre-delivery, trade-in, rental, or routine service, are often a mess of disconnected processes, legacy tools, manual effort, and guesswork.

But the truth is, they don’t have to be.

The equipment inspections struggle is real and it’s costing you

Before we talk about how to fix it, let’s talk about what’s broken.

- Workload management

Technicians are constantly firefighting. Between repairs, inspections, paperwork, and chasing missing information, they’re stretched thin and inspection quality suffers.

- Resource allocation

Do you know who’s inspecting what, and when? Most businesses don’t. Assignments are often made ad hoc, which leads to duplicated effort or critical delays.

- Equipment valuation

Trade-ins are high stakes. But without a standard, structured process, valuations can vary wildly depending on who’s inspecting and that erodes trust.

- Quality control

Manual inspections make it easy to skip steps, miss key observations, or fail to record faults properly. The result? Inconsistent quality and compliance risks.

- Communication gaps

Service advisors, technicians, and customers are often out of sync. Information lives in silos like paper forms, emails, spreadsheets, and by the time it gets shared, it’s already outdated.

- Data management

Inspection data is scattered, hard to search, and rarely connected to other systems like maintenance, finance, or customer records. That’s a huge missed opportunity.

- Customer expectations

Let’s be honest, customers today expect more. They want fast, transparent updates, visual documentation, and digital convenience. If you’re not delivering that, you’re behind.

The hidden cost of broken equipment inspections

And let’s not forget: inspections aren’t just about ticking boxes. They’re about protecting your brand, your reputation, and your bottom line.

Enter A365: Your digital equipment inspections game changer

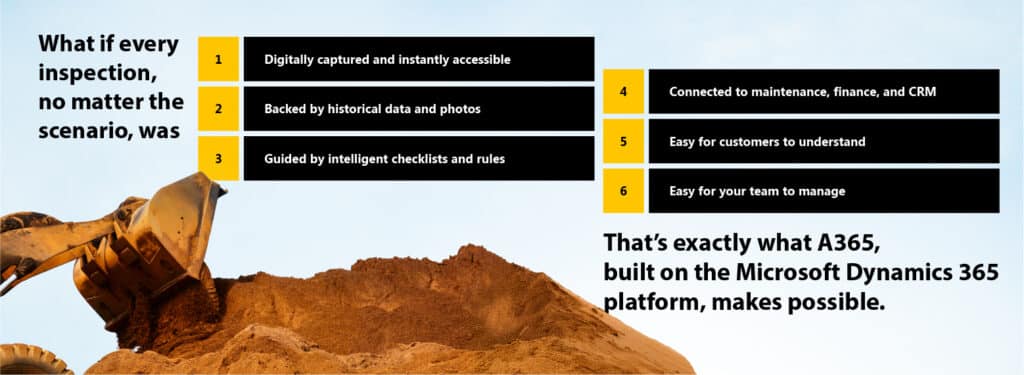

Now imagine a different reality.

A365 turns equipment inspections from chaos into cohesion

A365 is designed specifically for equipment businesses. It’s not a generic app or a bolt-on tool. It’s a fully integrated, end-to-end inspection solution that helps you:

- Digitize inspections (online or offline)

- Automate workflows

- Ensure compliance

- Streamline communication

- Capture rich data

- Delight customers

Let’s break that down.

What makes A365 so powerful?

Perform inspections with or without equipment on hand

You can use historical data to inspect an asset, even if it’s not physically present. This is especially useful for trade in valuations, fleet audits, or remote assessments.

Standardize observations

Whether it’s a pre-delivery equipment inspection, a service check, or a trade-in, you can record observations consistently across your entire business with no more “it depends on who did it.”

Build checklists once, use them everywhere

You can quickly define reusable checkpoints for different equipment inspection types by process step or equipment type. That means every technician follows the same structure every time.

Drive compliance and reduce risk

A365 lets you define rules that guide users during inspection entry. If a certain fault is observed, the system can prompt a follow-up action or enforce a photo capture.

Want to see how A365 can optimize your equipment operations? Explore our Digital Experience Center for a free, immersive look.

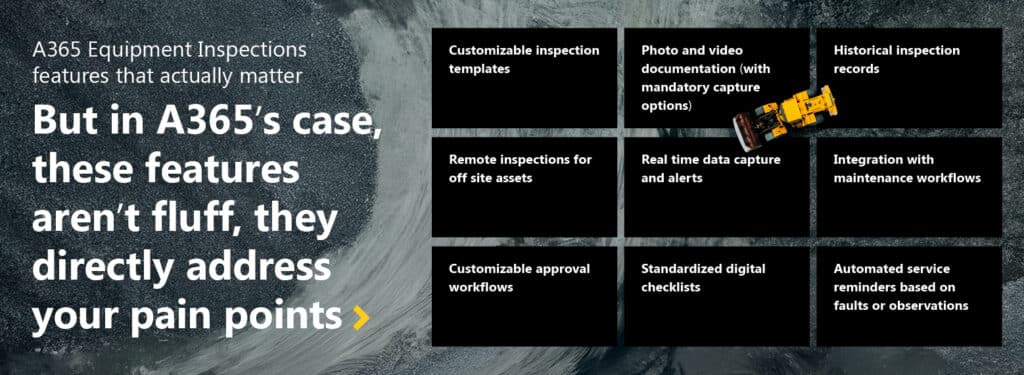

A365 Equipment Inspections features that actually matter

Let’s be real, “feature lists” can get boring fast.

In short, it’s everything your inspection process needs, all in one place, all connected, all digital.

Real-world coverage for every scenario

Here’s what A365 Equipment Inspections covers in practical, day-to-day terms:

- Scheduled inspections: plan and manage routine checks before they become urgent

- Process-based checklists: tailor inspections by workflow step (for example, pre-delivery, post-service)

- Equipment type checklists: different machines need different checks and A365 makes that simple

- Service reminders: automatically flag follow-ups based on inspection findings

- Checkpoint rules: enforce best practices during the inspection itself

- Trade in inspections: standardize valuation for fair, accurate pricing

- Rental inspections: separate workflows for rental returns and pre-rental checks

- Mandatory photos or videos: no more “he said, she said.” Visual evidence is built in

- Safety checks: ensure compliance with regulatory standards

How it looks in action

Imagine this:

A technician is assigned a rental return inspection. He pulls up the checklist on his tablet, walks through each checkpoint, takes required photos of any damage, and the system automatically flags a fault that needs service.

A service advisor is instantly notified, the customer receives a summary with photos, and the work order is created, all without a single email or phone call.

That’s not a dream, that’s A365 in action.

Why the A365 and Microsoft Dynamics 365 combo matters

A365 isn’t just a standalone tool, it’s built on Microsoft Dynamics 365 and other technologies from the Microsoft ecosystem, including Azure, Copilot, Power Platform, and Dataverse.

That’s a big deal. You’re not adopting “yet another app,” you’re extending the platform you already trust.

The ROI is clear

When you bring A365 Equipment Inspections into your toolbox, you:

- Reduce manual effort

- Improve inspection accuracy

- Capture billable work you were missing

- Shorten customer response times

- Improve customer satisfaction

- Strengthen your brand’s reputation for quality

And you do it all with minimal risk and investment because you’re building on a platform that’s already proven.

Final thoughts: Equipment inspections shouldn’t be a headache

Inspections are one of the most critical and overlooked parts of the equipment lifecycle. They impact everything from safety and compliance to customer trust and profitability.

But too many businesses treat equipment inspections like a necessary evil instead of a strategic advantage.

With A365 built on Microsoft Dynamics 365, you can finally fix what’s broken:

- Eliminate paper and spreadsheets

- Standardize processes across your business

- Empower technicians with digital tools

- Keep customers informed with transparency

- Capture more value with accurate data

In short, you can turn inspections from chaos into clarity.

If your equipment inspections process feels like it’s held together with duct tape and hope, it’s time for a change. A365 can help you get there.

Interested in seeing A365 in action? Let’s talk.