The heavy equipment industry has always been defined by grit. From building the roads we drive on, to mining the minerals in our smartphones, to cultivating the food that feeds billions, your machines don’t just move dirt, they move the world forward.

But if the last few years have shown us anything, it’s that steel and horsepower alone aren’t enough anymore. The challenges you face as an equipment business have shifted. It’s now more about delivering uptime, managing risk, ensuring compliance, and creating customer relationships that last beyond a single sale.

And in 2026, the real battleground isn’t just the jobsite, it’s in the systems that power your business behind the scenes.

This year, digital transformation is no longer a buzzword, it’s table stakes. From AI agents that handle service requests before a technician even gets in the truck, to supply chain networks that give you real-time visibility of parts shortages, the companies who thrive are the ones who turn business complexity into clarity.

At Annata, we’ve spent decades shoulder to shoulder with equipment businesses, OEMs, dealers, rental providers, learning your language, your pain points, and the realities of your industry. And in this article, we’ll walk through the equipment industry trends for 2026, and show how a platform like A365 is designed specifically to help you turn disruption into opportunity.

Equipment industry trends for 2026 – Trend 1: AI agents that work like extra team members

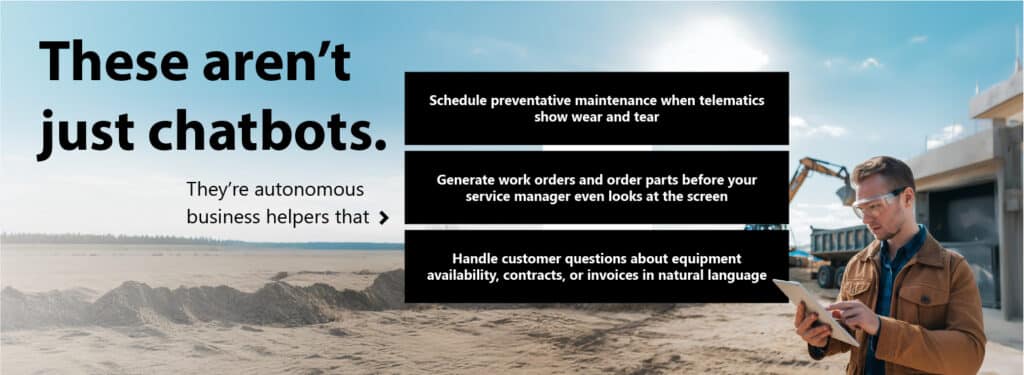

Every dealer and rental manager knows the pain of chasing service tickets, juggling warranty claims, and trying to keep customers happy when labor is already stretched thin. Enter AI agents.

Imagine having an always-on, 24/7 colleague who doesn’t get tired, doesn’t forget, and doesn’t need overtime pay. That’s the role AI agents are now playing inside equipment businesses.

And it’s not theory, it’s already happening. Forward-looking equipment dealers are using AI copilots inside Microsoft Dynamics 365 (and by extension, A365) to free service teams from repetitive tasks, letting them focus on what actually matters: getting machines back to work and customers back to producing.

Equipment industry trends for 2026 – Trend 2: Supply chain connectivity that actually works

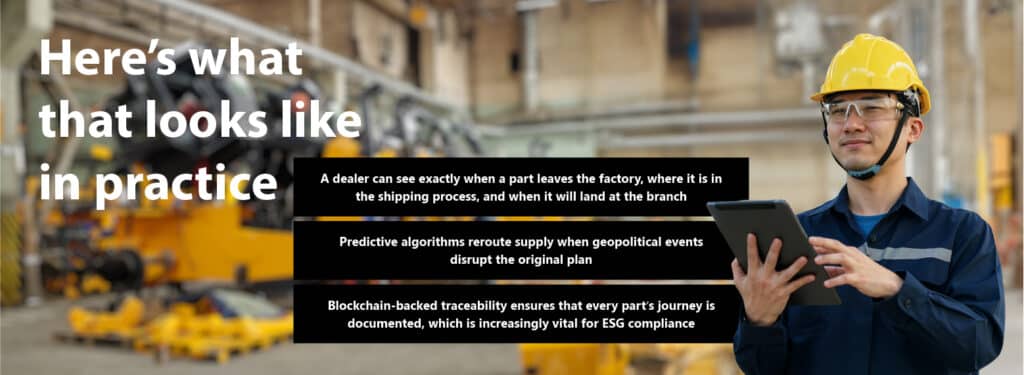

If you’re in equipment, you’ve lived the nightmare: a critical component is stuck in transit, a global disruption spikes prices overnight, or you can’t promise a delivery date because no one can give you a straight answer on when that excavator will leave the factory.

Supply chain pain has become an all too familiar headache. But in 2026, companies are finally gaining the upper hand through real-time supply chain networks.

These solutions aren’t just about tracking shipments. They’re about connecting the dots between OEMs, dealers, rental houses, logistics providers, and even regulators in one transparent ecosystem.

For equipment businesses, this means no more crossed fingers when making promises to customers. You can commit with confidence, because you’ve got visibility from end to end.

Equipment industry trends for 2026 – Trend 3: AI-driven decision engines in the back office

In the past, executives made decisions based on gut feel and end-of-month reports. But by the time the numbers came in, the job was already done and the margin was already lost.

For example, a fleet manager can now see not just utilization rates, but the exact moment a machine is about to move from profitable to unprofitable. Finance leaders can get a live readout of cash flow exposure tied to supply chain delays.

The shift is huge: businesses move from reacting to problems to preventing them before they occur.

Equipment industry trends for 2026 – Trend 4: Digital twins for fleets and beyond

Digital twins used to be reserved for R&D labs. Today, they’re practical tools running in live equipment businesses.

What’s changed? Instead of just simulating a machine, digital twins now replicate entire fleets, projects, and even supply chains.

This means you can:

- Run “what if” scenarios on fleet downtime and project impact

- Test how a new sustainability initiative will affect your carbon reporting

- Simulate cash flow under different rental utilization rates

For equipment leaders, this isn’t just a tech showcase, it’s a decision-making engine with dollars attached.

Equipment industry trends for 2026 – Trend 5: Workforce augmentation with AR, VR, and copilots

Finding skilled labor is still one of the toughest challenges in the industry. Younger generations aren’t rushing into operator cabins or service bays, and the experienced workforce is aging.

That’s where technology is stepping in as a force multiplier:

- AR glasses walk a junior technician through a complex hydraulic repair step by step

- Remote inspections allow one expert to support multiple sites without ever leaving the office

- Copilot features inside A365 simplify everything from financial reporting to customer communication

Instead of trying to replace people, these tools make every worker more capable and confident, even when they’re new to the job.

Equipment industry trends for 2026 – Trend 6: Rental and equipment-as-a-service

More and more, customers aren’t looking to own, they’re looking to access. Flexibility, cash preservation, and reduced maintenance responsibility are driving the growth of rental and subscription models.

The difference in 2026? These models are being digitally transformed:

- Rental contracts are automatically tied to machine telematics

- Billing is automated based on actual usage, not estimates

- Customers can log into self-service portals to track costs, schedules, and equipment availability in real time

The result: higher satisfaction, smoother revenue streams, and a business model that scales with customer demand.

In 2026, success in the equipment industry depends on more than just the machines you sell or rent. It’s about how seamlessly you can connect your business systems with the OEM brands you represent.

Dealers and rental providers are increasingly expected to deliver the same level of transparency and digital experience that customers already get directly from manufacturers. That means integrations are no longer “nice to have”, they are business-critical.

Here’s what these integrations enable:

- Real-time equipment data sharing: Telematics flows directly from OEM systems into dealer and rental platforms.

- Connected service management: Warranty claims, service bulletins, and recalls are automatically synced with OEM databases.

- Unified customer experience: Customers see a single source of truth across OEM and dealer portals for service history, parts availability, and equipment status.

- Faster parts and maintenance cycles: OEM inventory and dealer supply chains are linked, reducing lead times and boosting uptime.

The result is a tighter, more collaborative ecosystem where OEMs, dealers, and customers all operate with the same information. Trust is no longer just about equipment performance, it’s about how well systems work together.

What does this mean for equipment businesses?

All these trends come down to one thing: the ability to adapt faster than the market changes.

- Agility and flexibility: AI agents and decision engines make it possible to pivot strategies instantly

- Resilience: Connected supply chains and digital twins ensure businesses can handle disruptions without missing a beat

- Customer loyalty: Transparent rental models, personalized service, and proactive maintenance create relationships that last

- Sustainability: Circular economy reporting, battery lifecycle management, and ESG compliance are seamlessly integrated

The businesses that win in 2026 aren’t the ones with the biggest machines. They’re the ones with the smartest business solutions.

Why A365 is built for this moment

At Annata, we know these challenges aren’t just theoretical. We’ve walked shop floors, sat in dealer back offices, and worked through late-night calls when equipment downtime threatened to derail a customer’s project.

That’s why we built A365, not as a generic ERP, but as a business solution made for the equipment industry.

[Reminder] Don’t forget to claim your free access to our Digital Experience Center. Get an exclusive look at how A365 can power new possibilities for your business as your company takes on the equipment industry trends for 2026 head-on. Enter your email to get started.

Powered by Microsoft Dynamics 365

At the core of A365 is Microsoft Dynamics 365, the global standard for modern enterprise solutions. This means your business gets the best of both worlds:

- Proven enterprise backbone: Finance, operations, and CRM capabilities trusted by thousands of businesses worldwide

- Seamless integration: A365 adds deep, industry-specific functionality on top of Dynamics 365, so your teams don’t juggle disconnected systems

- Future-ready innovation: with Microsoft Azure, Copilot, and Power Platform, you gain continuous innovation without disruption

In short, A365 speaks your language because it was built in your world, on a platform you can trust.

Conclusion: From disruption to mastery

The heavy equipment industry in 2026 is at a crossroads. The disruptions of the past few years have evolved. But so have the tools we use to face them.

Having had a look at the equipment industry trends for 2026, AI, connectivity, and digital integration are practical, business-critical solutions that determine whether you can deliver uptime, control costs, and keep customers loyal.

And with A365, Annata offers not just technology, but decades of industry understanding baked into every feature. We’re your trusted partner that knows what keeps you up at night and how to turn those pain points and the equipment industry trends for 2026 into competitive advantages.

In 2026, success belongs to the businesses that embrace not just digital transformation, but digital mastery. Let’s get there together. Connect with us today to find out more.