Digital transformation has become a priority across many industries, but for companies with long histories of success, the path is not always straightforward. The reality for many enterprises is that their operations still rely on technology platforms that were built decades ago. These systems once served their purpose, but today they limit growth, efficiency, and customer satisfaction.

One of the clearest examples comes from JM Family Enterprises, a privately held automotive distribution and logistics leader based in Deerfield Beach, Florida. JM Family generates more than 22 billion dollars in annual revenue and is best known for its subsidiary Southeast Toyota Distributors (SET). SET is the largest independent distributor of Toyota vehicles in the world, supplying over 500,000 vehicles each year to 177 dealers, which represents almost 20 percent of Toyota’s U.S. sales.

In addition to vehicle distribution, JM Family Enterprises has built a significant business in parts and accessories, with 670 million dollars in Toyota-certified parts sold in 2024 alone.

With numbers like these, JM Family Enterprises is widely seen as an industry success story. Yet even an organization of this scale found itself constrained by an outdated technology foundation. Their decision to modernize offers valuable lessons not just for automotive distribution but for the entire automotive ecosystem.

The challenge: A legacy system at its limit

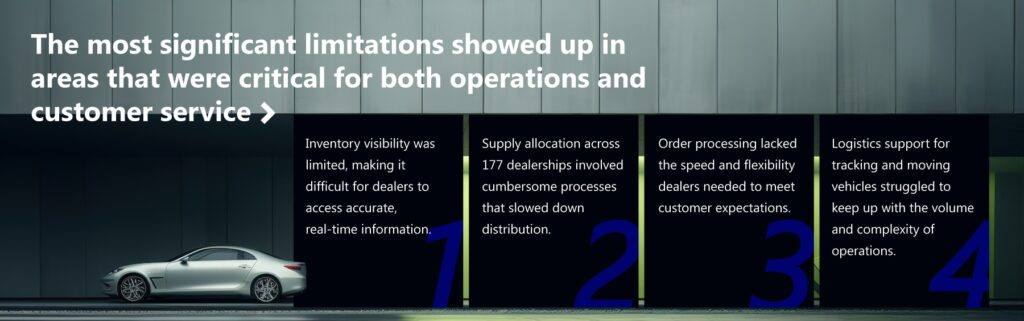

For more than forty years, JM Family Enterprises operated on a mainframe platform supported by a “green screen” interface. Over time, this system grew into a patchwork of more than 200 applications. It had been stable and dependable for many years, but as expectations shifted, its weaknesses became clear.

This challenge is one that many companies in the automotive sector recognize. Legacy systems often come with high maintenance costs and limited integration options, and they make it harder for businesses to respond to disruptions or changing customer needs.

Why JM Family Enterprises chose to modernize

The leadership team at JM Family realized that continuing to maintain and extend the existing system would not deliver the improvements dealers were asking for. Incremental updates could no longer close the gap between what the system could do and what the business required.

The move was not just about addressing current inefficiencies. It was also about positioning JM Family for the future. The automotive industry is undergoing rapid transformation, from the rise of electric vehicles to global supply chain volatility to customers expecting digital-first experiences. JM Family Enterprises needed a foundation that could adapt to these shifts.

The solution: A365 and Dynamics 365

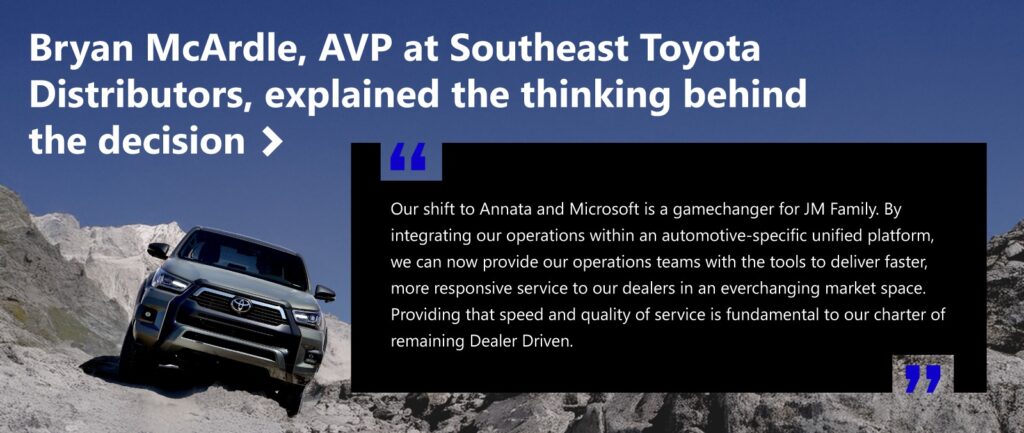

After evaluating options, JM Family Enterprises selected Annata’s A365 platform, built on Microsoft Dynamics 365, which is specifically designed for the automotive sector. This combination allowed them to replace their fragmented system with an integrated platform that covers the entire vehicle lifecycle.

By choosing a solution tailored to automotive distribution rather than a generic enterprise system, JM Family Enterprises ensured that the new platform would align closely with their needs.

Building confidence across the organization

Adopting a new system of this scale required more than just selecting technology. JM Family Enterprises needed to bring its people along on the journey. To build confidence, Annata led 30 consecutive days of demonstrations, with support from Microsoft’s Toyota account team. Nearly 200 stakeholders participated, ranging from executives to operational staff to dealer representatives.

These sessions gave employees and partners the opportunity to see how the platform would handle real business scenarios, and they created space for questions and feedback. The result was not just technical validation but also cultural alignment. By the time the decision was made, the people who would rely on the system had already seen how it could improve their work.

This approach shows that modernization projects succeed when they are transparent and collaborative.

Lessons for automotive leaders

Legacy systems eventually create strategic risk

For a time, legacy platforms may feel dependable. They are familiar, and the costs of maintaining them can appear manageable. Over time, however, the limitations accumulate. In a competitive market where speed and transparency define success, these systems can slow growth and erode customer trust.

Industry-specific solutions reduce friction

Automotive workflows, from vehicle allocation to warranty management, come with unique requirements. Platforms designed with these realities in mind reduce the need for customization and deliver value more quickly. JM Family’s choice of Annata A365 reflects this principle.

Transformation requires broad engagement

Technology adoption is not just a technical decision. It affects how employees work and how dealers interact with the company. JM Family’s decision to involve 200 stakeholders early in the process ensured smoother adoption and stronger buy-in.

Long-term alignment matters more than short-term convenience

JM Family Enterprises selected its technology platform before choosing an implementation partner. This sequence kept the focus on strategic alignment rather than on immediate implementation details.

Industry relevance within automotive

The challenges that drove JM Family to modernize are not unique. Similar pressures are reshaping every corner of the automotive sector.

- Automakers are adapting production and distribution systems to accommodate electric vehicles, manage supply shortages, and respond to fluctuating demand. Platforms that can manage complex networks with speed and accuracy are essential.

- Dealers must provide a digital-first experience to customers who expect accurate delivery timelines and real-time visibility into vehicle availability. Many dealer management systems built decades ago cannot meet these requirements.

- Parts and service providers handle large inventories, warranty claims, and aftermarket demand. Without modern systems, ensuring the right part reaches the right customer at the right time becomes a major challenge.

- Rental and mobility services are becoming an increasingly important extension of the automotive lifecycle. Fleet management and customer satisfaction both rely on integrated systems.

- Logistics operators working within the sector need accurate end-to-end tracking from factory to dealership to keep vehicles moving and customers informed.

In each of these areas, outdated technology slows progress. Companies that invest in modernization gain the flexibility to adapt and the efficiency to compete.

Looking ahead

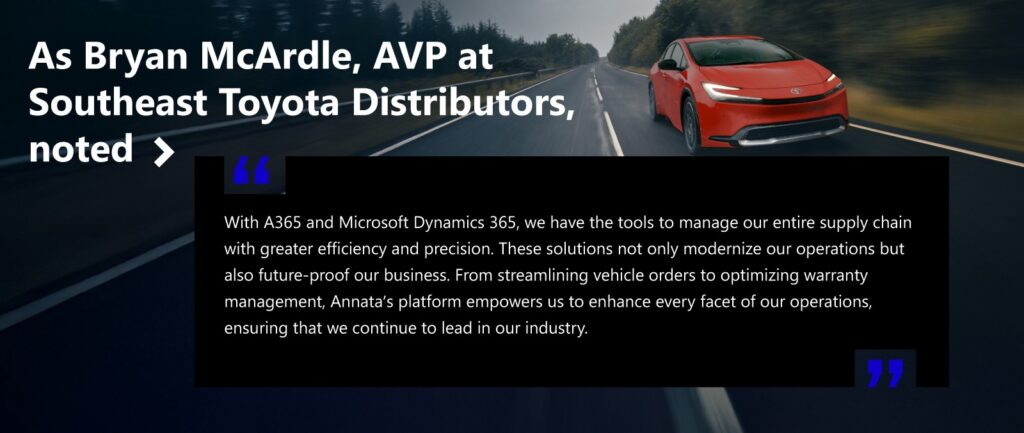

For JM Family Enterprises, the adoption of A365 and Dynamics 365 is not just a technology upgrade but a step toward greater adaptability and long-term resilience.

A practical roadmap for modernization

Drawing on JM Family’s journey, here are five steps automotive organizations can consider as they plan their own modernization initiatives:

- Calculate the true costs of legacy systems. Look beyond maintenance budgets to account for inefficiencies, errors, and missed opportunities.

- Evaluate industry-specific platforms. Systems built for automotive distribution, retail, or manufacturing will reduce complexity and speed up deployment.

- Engage stakeholders early and often. Broad involvement helps uncover concerns and build trust across the organization.

- Select the right platform before the implementation partner. This keeps long-term goals in focus and prevents short-term decisions from shaping strategy.

- Treat modernization as a strategic investment. Technology is part of the foundation that enables growth, not just a tool for day-to-day operations.

Conclusion

JM Family Enterprises demonstrates how even the most successful automotive companies can reach a point where legacy systems limit their potential. Their decision to modernize with A365 and Dynamics 365 has positioned them to serve dealers more effectively, reduce operational friction, and prepare for the future of the industry.

For automotive leaders, the key takeaway is that modernization delivers more than efficiency. It enables the visibility, accuracy, and adaptability needed to compete in a market defined by constant change. Companies that recognize the limits of their legacy systems and act proactively will be the ones best positioned to continue leading the industry.

Read JM Family’s journey through operational evolution in this case study.